How 3D Printing is Affecting Global Supply Chain Models

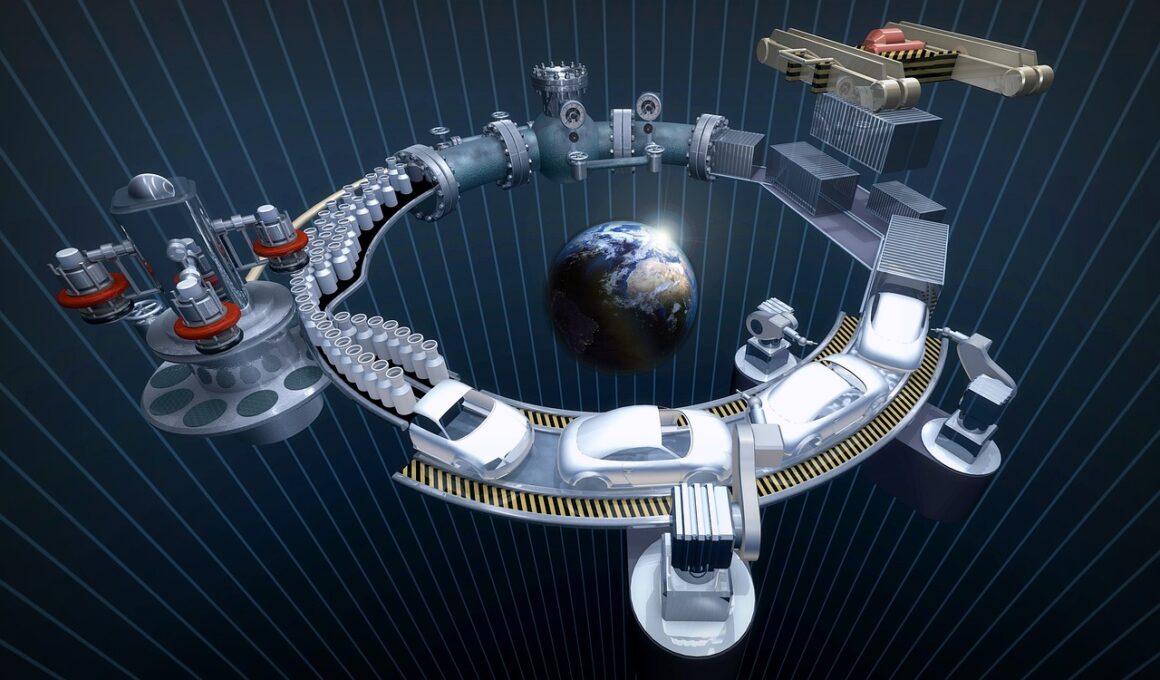

3D printing is transforming global supply chain models by introducing unprecedented levels of flexibility and efficiency. In traditional supply chains, manufacturers often faced challenges related to inventory management, lead times, and logistics. With the integration of 3D printing technology, companies can produce goods on-demand, thereby significantly reducing excess inventory and associated carrying costs. Furthermore, the ability to quickly design and iterate on products accelerates the innovation cycle, allowing businesses to respond to market changes promptly. This revolutionizes the production process by enabling localized manufacturing capabilities. As a result, there is a shift from central factories to decentralized production sites. Companies can leverage this technology to customize products based on regional preferences, thus enhancing customer satisfaction. Moreover, 3D printing encourages collaboration among suppliers and manufacturers, allowing for faster prototyping and production trials. By streamlining operations and minimizing waste, organizations can achieve more sustainable practices in their supply chains. Ultimately, these factors contribute to a more resilient and adaptable global supply chain, paving the way for new business models and opportunities in various industries.

To understand how 3D printing impacts global supply chains, it’s essential to explore its key benefits. First, 3D printing eliminates long lead times typically associated with traditional manufacturing processes. Parts can be produced closer to the end-user, reducing shipping time and costs. Localized production means that businesses can remain agile, quickly adapting to shifts in demand. Second, this technology enhances product customization, catering to individual consumer needs effectively. Companies can offer personalized products without significantly increasing production costs. Third, reducing reliance on extensive supplier networks contributes to a more streamlined supply chain, as fewer intermediaries are involved. This not only minimizes potential disruptions but also lowers risks associated with inventory and logistics. Additionally, 3D printing fosters sustainability by reducing material waste and energy consumption during production. By optimizing resources, companies can meet their environmental goals while improving their bottom line. The simplification of design and manufacturing processes fosters innovation, enabling businesses to experiment with new materials and designs. Altogether, 3D printing represents a significant leap forward, signaling a new era in global supply chain strategies.

Challenges of Integrating 3D Printing into Supply Chains

Despite its numerous advantages, integrating 3D printing into global supply chains presents several challenges that organizations must address. One significant hurdle is the initial investment in technology and training. Adopting 3D printing requires not only capital expenditure on machines and software but also upskilling employees to operate and maintain them effectively. This can slow down the adoption process, particularly for small to medium-sized enterprises (SMEs) with limited budgets. Furthermore, transitioning from traditional production methods to additive manufacturing may introduce complexities in quality assurance and regulatory compliance. Businesses must ensure that the printed products meet industry standards and customer expectations while navigating the evolving legal landscape surrounding 3D printing technologies. Additionally, managing intellectual property risks is imperative, as the ease of reproducing designs raises concerns about patent infringements and counterfeit products. Supply chain managers need to develop strategies to safeguard proprietary designs to maintain a competitive edge. Finally, businesses must contend with the complexities of material compatibility and supply. Not all materials are suitable for 3D printing, and sourcing the right materials can pose challenges that impact overall efficiency.

The impact of 3D printing on logistics is another crucial consideration. Traditional supply chains heavily rely on transportation networks that connect suppliers with manufacturers and consumers. However, as companies begin to adopt 3D printing, the need for extensive logistics networks may decline. This shift challenges freight and delivery industries to adapt to new business models. Notably, the ability to manufacture products at proximity can lead to reduced transportation costs and emissions, contributing to global sustainability goals. Additionally, organizations can explore new distribution strategies that leverage local 3D printing hubs or services, ultimately decreasing reliance on centralized warehouses. However, the logistics sector must evolve to accommodate on-demand manufacturing and distribution, which may lead to increased variability and unpredictability in supply chain operations. Companies will need to invest in software and systems that can handle real-time inventory management, adapting to the unique challenges that arise from decentralized production. In summary, while 3D printing offers promising efficiencies, the logistics ramifications require careful planning and an embrace of innovative transportation solutions to ensure a seamless transition.

The Future of Global Supply Chains with 3D Printing

Looking ahead, the integration of 3D printing into global supply chains is expected to redefine manufacturing paradigms significantly. We can anticipate a future where products are not only designed faster but also delivered to customers with unprecedented efficiency. As the technology becomes more mainstream, innovations will lead to improved materials that offer greater strength, flexibility, and functionality. Additionally, advancements in 3D printing techniques, such as multi-material printing, will enable a wider range of applications across various industries. The convergence of 3D printing with other technological advancements, like the Internet of Things (IoT) and artificial intelligence (AI), will further enhance supply chain capabilities. These technologies can facilitate real-time monitoring and data-driven decision-making, optimizing operations in previously unattainable ways. Furthermore, as more companies adopt 3D printing, collaboration and knowledge-sharing across industries will foster competition and innovation, driving down costs and enhancing access to sophisticated manufacturing technologies. Overall, the future of global supply chains represents a profound shift towards more agile, efficient, and responsive production systems in which 3D printing plays a central role.

The growing awareness of environmental sustainability is further pushing the adoption of 3D printing in supply chains. As companies strive to reduce their carbon footprints, the benefits of localized, on-demand production become increasingly apparent. Products can be manufactured close to where they are needed, diminishing the environmental impact of long-distance transportation. Moreover, 3D printing significantly reduces material waste compared to traditional subtractive manufacturing methods. By using only the necessary resources to create a product, organizations can align their practices with sustainable development goals while maintaining profitability. This emphasis on sustainability also encourages consumers to support brands that demonstrate eco-friendly initiatives, making it a crucial competitive advantage. Companies that effectively integrate 3D printing into their supply chains can market their sustainability efforts, attracting conscientious consumers. In light of regulatory pressures and societal expectations, businesses must adapt their strategies to incorporate sustainable practices throughout their operations. Thus, 3D printing serves as a tool that not only enhances operational efficiency but also empowers organizations to advance their sustainability agendas and contribute to global environmental efforts.

Conclusion

In conclusion, 3D printing has a profound and lasting influence on global supply chains. By enhancing production flexibility, reducing lead times, and fostering sustainability, this technology reshapes conventional manufacturing paradigms. However, companies must navigate the challenges associated with its integration, such as initial setup costs, quality assurance, and logistical considerations. The future of supply chains will likely involve a more decentralized approach, leveraging local production capabilities to enhance responsiveness and mitigate risk. As organizations embrace 3D printing, they will not only improve operational efficiencies but also adapt to changing market demands and consumer preferences. This transformative technology paves the way for smarter, more resilient supply chains that can withstand global challenges. By rethinking traditional models and embracing innovation, businesses stand to gain a competitive edge in an increasingly complex market landscape. Ultimately, 3D printing signifies a new chapter in supply chain management, encouraging continuous improvement and agile responses to evolving business environments. As its potential unfolds, organizations must remain vigilant and proactive in adopting this technology to harness its benefits effectively.

Embracing Innovation for a Competitive Edge

In summary, the impact of 3D printing on global supply chains presents both opportunities and challenges. Businesses that effectively leverage this technology are poised to innovate, reduce costs, and meet customer expectations more efficiently. The successful integration of 3D printing allows companies to optimize their supply chain dynamics, enhance product offerings, and achieve greater operational resilience. As the technology matures, its applications will become increasingly sophisticated, contributing to evolving supply chain strategies. Companies that fail to recognize and adapt to these shifts risk losing their market position to more agile competitors. Therefore, continuous investment in research and development will be crucial for organizations to stay ahead of the curve. Furthermore, fostering a culture of innovation and collaboration among stakeholders will drive advancements in 3D printing adoption. To thrive in this rapidly changing landscape, businesses need to remain agile, responsive, and willing to embrace emerging technologies as they explore unconventional pathways to success. By seizing the moment, organizations can navigate the complexities of modern supply chains while effectively harnessing the transformative power of 3D printing.