Overcoming Common Pitfalls in Cross-Docking Implementations

Cross-docking, an effective logistics strategy that minimizes storage costs, often faces implementation challenges. Numerous businesses struggle with common pitfalls that can hinder its efficiency. First, a lack of proper planning can derail the entire process. Without a well-structured plan, multiple bottlenecks can arise, jeopardizing overall supply chain efficiency. Second, insufficient communication amongst teams creates misunderstandings, leading to errors in inventory management. To avoid these issues, organizations must establish clear communication channels. Third, underestimating training requirements can result in unskilled personnel handling critical operations. Employees should be provided adequate training on their roles within the cross-docking process. Next, reliance on outdated technology can hamstring performance. Investing in the latest software and tools can significantly enhance operational effectiveness. Similarly, ignoring data analysis prevents informed decision-making. By leveraging data, businesses can optimize their cross-docking processes and identify improvement areas. Additionally, inadequate space management can lead to congestion, making it vital for companies to assess layout regularly. Finally, failure to engage management support can stifle progress. Leadership’s commitment to cross-docking is essential for fostering a culture of improvement and operational excellence.

The importance of stakeholder involvement in cross-docking implementations cannot be overstated. Each stakeholder plays a significant role in the success of the process, and their insights can help mitigate potential challenges. For example, logistics, warehousing, and transportation teams should collaborate closely. This collaboration helps in understanding bottlenecks and developing solutions. Aligning stakeholder goals ensures that everyone works towards a common objective, creating a seamless flow of operations. In addition to internal teams, including suppliers and customers in the conversation also enhances results. Their feedback fosters a more customer-centered approach, leading to improved service levels. Regular stakeholder meetings help keep everyone informed and engaged, avoiding misunderstandings. Moreover, feedback mechanisms should be in place to capture suggestions or concerns promptly. This proactive approach fosters an inclusive environment, making everyone feel valued. Alongside stakeholder involvement, setting realistic expectations is crucial. Overlooking the complexity of the implementation can lead to frustration and project failure. Providing stakeholders with realistic timelines, costs, and potential setbacks can yield better cooperation and results. Effectively managing expectations helps create achievable milestones that boost morale and progress along the way.

Emphasizing Continuous Improvement

Another critical aspect to consider in cross-docking implementations is the need for continuous improvement. Companies must adopt a mindset that encourages ongoing assessment of their processes. Establishing key performance indicators (KPIs) allows teams to measure their effectiveness and identify improvement areas consistently. Regularly reviewing these KPIs in team meetings promotes accountability, ensuring everyone remains focused on meeting goals. A culture of continuous improvement can lead to innovative solutions that enhance operations over time. Embracing feedback from frontline workers can offer valuable insights, as they are the ones directly involved in the daily activities. Creating an open environment welcomes suggestions, driving innovation and efficiency. Utilizing technologies like warehouse management systems (WMS) can also support ongoing improvements. These systems provide real-time data and analytics, enabling teams to react promptly to challenges. Additionally, forming cross-functional teams promotes collaboration and allows diverse ideas to flourish. By encouraging all employees to contribute, organizations can evolve their cross-docking processes healthily. Furthermore, recognizing and rewarding improvements fosters a positive work atmosphere. Celebrating success encourages employees to maintain performance and stay invested in organizational goals.

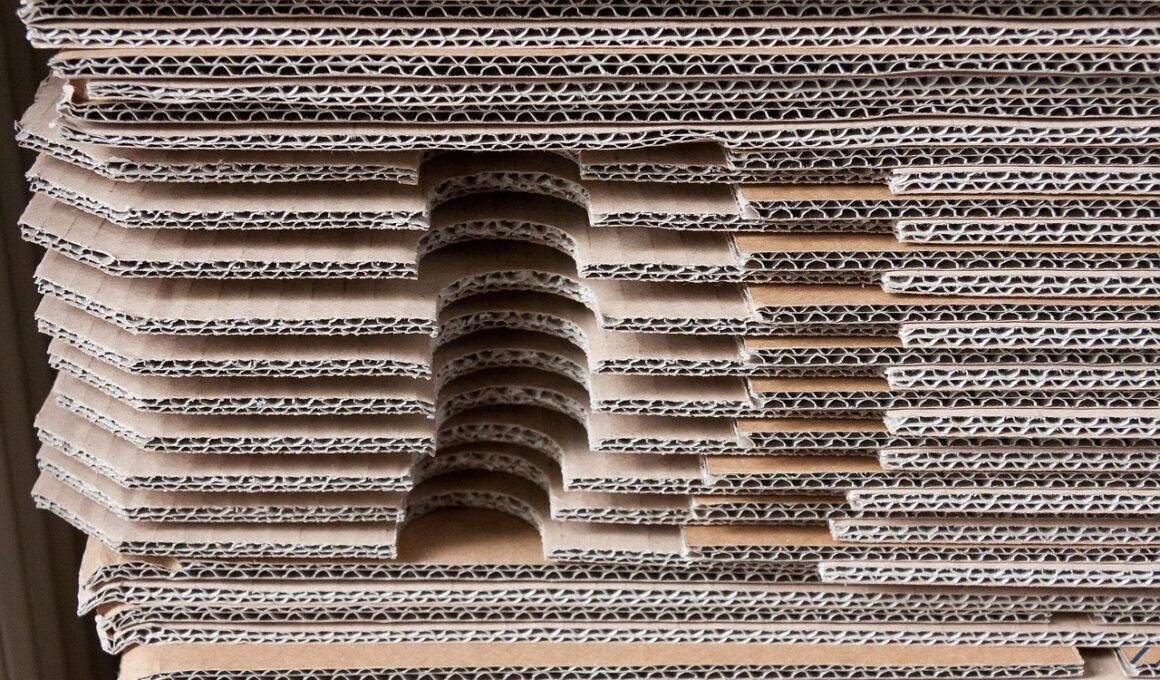

In addition to focusing on improvement, evaluating current warehouse infrastructure is essential. An efficient cross-docking operation requires facilities suitably designed for rapid product movement. Organizations must analyze existing layouts and storage capacities, ensuring they are optimized for swift processing. An overcrowded or inadequately configured warehouse can drastically slow down transfer times, leading to delays and increased costs. Conducting space audits can help identify areas needing enhancement for cross-docking efficiency. Strategically placing inbound and outbound areas can streamline the flow, minimizing transit times within the warehouse. Utilizing technology, such as robotic process automation (RPA), can further enhance efficiency by automating repetitive tasks. Furthermore, improving visual management systems ensures high visibility of processes, reducing errors caused by confusion. Adequate training for all personnel involved in cross-docking operations helps them understand facility layouts better. When employees know how to navigate the warehouse efficiently, they can enhance operational speed and accuracy. Implementing these strategies not only boosts productivity but also positively impacts customer satisfaction. By meeting customer demands quickly and efficiently, businesses can foster long-lasting relationships and drive loyalty in their clientele.

Adapting to Market Changes

Moreover, businesses should be adept at adapting to evolving market conditions. The landscape of supply chain management is always changing, necessitating flexibility within cross-docking operations. Market trends, consumer preferences, and technological advancements can all influence cross-docking strategies. Companies that cling to outdated practices may find themselves quickly outpaced by more adaptive competitors. Regularly monitoring market trends enables organizations to adjust operations proactively according to customer expectations. Additionally, maintaining strong relationships with suppliers enhances adaptability, allowing for prompt responses to changing circumstances. Innovative supply chain technologies like blockchain provide transparency and traceability, essential for adapting to market demands. Using data analytics can help predict shifts in consumer behavior, enabling organizations to anticipate inventory needs effectively. Embracing a dynamic approach helps businesses remain relevant and competitive in their respective industries. Establishing an agile supply chain not only fosters operational efficiency but also builds customer trust. When customers observe a company’s ability to meet expectations consistently, it increases their willingness to engage with the brand. Ultimately, adaptability is crucial for sustainable success in cross-docking operations, ensuring companies remain competitive and viable in their markets.

Preparing for potential disruptions should also be part of any cross-docking strategy. Businesses must consider various risks, including natural disasters, economic shifts, and supply chain interruptions. By assessing these risks, organizations can develop contingency plans that minimize operational downtime. A comprehensive risk management strategy involves collaboration with stakeholders to identify vulnerabilities. Training employees on how to handle disruptions effectively is crucial for maintaining productivity under pressure. Regularly updating these plans ensures they remain relevant and effective against evolving threats. Additionally, investing in technology can bolster resilience and facilitate faster recovery. Forms of technology like cloud-based supply chain systems enhance agility and enable real-time decision-making during crises. Moreover, diversifying suppliers can mitigate risks associated with supplier dependency. When one supplier faces challenges, having alternatives in place ensures continuity of supply without significant delays. Engaging in scenario planning allows companies to prepare for various outcomes and respond swiftly. Creating a culture of resilience at all organizational levels empowers employees to remain solution-focused. By anticipating disruptions and developing strategies to manage them, businesses position themselves for success even during challenging times.

The Role of Technology in Cross-Docking Success

Lastly, leveraging technology is vital for streamlining cross-docking implementations effectively. Businesses can significantly enhance operational efficiency by integrating advanced technologies into their processes. Warehouse management systems (WMS) offer automation capabilities that minimize manual errors and improve inventory accuracy. Utilizing RFID technology provides real-time visibility into inventory levels and streamlines tracking, leading to more efficient operations. Additionally, investing in automated guided vehicles (AGVs) allows for swift product movement within the warehouse. Adopting these innovative solutions helps organizations cut down on labor costs while maximizing performance. Furthermore, implementing predictive analytics ensures proactive inventory management. Analyzing historical data can identify trends in demand, allowing for more precise forecasting and reduced stock discrepancies. Additionally, cloud-based systems enhance collaboration across the supply chain, enabling seamless information sharing among all stakeholders. This transparency fosters better decision-making and enhances overall performance. When organizations harness technology, they can reduce processing times, improve customer satisfaction, and respond promptly to market demands. Ultimately, the integration of technology in cross-docking plays a critical role in driving organizational success, helping companies achieve their strategic objectives.

By understanding and addressing these common pitfalls in cross-docking implementations, businesses can significantly enhance their operational efficiency. Fostering collaboration among stakeholders, focusing on continuous improvement, evaluating warehouse infrastructure, adapting to market changes, preparing for disruptions, and leveraging technology create an adaptive approach that provides resilience in a competitive landscape. Investing in employee training and fostering a culture of feedback ensures that the workforce is equipped to handle challenges and provides innovative solutions. Regularly revisiting strategies and plans fortifies an organization’s ability to respond efficiently to disruptions or changing market demands. This proactive approach to cross-docking implementation allows companies to optimize their supply chain processes while enhancing customer satisfaction. Companies that truly grasp the intricacies of cross-docking stand much better chances of revitalizing their operational framework, achieving better cost management, and accommodating fluctuating consumer expectations. As logistics continues evolving, businesses must remain agile and open to adopting new practices that enhance efficiency and reduce waste. Only then can companies fully unlock the potential of cross-docking within the realm of supply chain management.