Optimizing Safety Stock Levels Amid Demand Uncertainty

In today’s volatile market, effective supply chain management is crucial for businesses striving to meet customer demands while minimizing costs. Demand variability can significantly impact inventory levels, leading to either stockouts or excess inventory. To address these challenges, companies must optimize their safety stock levels. Safety stock acts as a buffer against unpredictable fluctuations in demand, ensuring that businesses can fulfill orders without delays. By accurately assessing demand variability, companies can develop effective strategies for determining the appropriate safety stock levels. Various methods exist for estimating demand variability, including statistical forecasting techniques and advanced analytics. Implementing these strategies can help businesses maintain a competitive edge and enhance customer satisfaction. Moreover, organizations should monitor their safety stock continuously, adjusting it as market conditions change. This dynamic approach enables businesses to respond swiftly to shifts in demand patterns. By leveraging technology and data analytics, companies can optimize their inventory management, maximizing efficiency while minimizing costs. As a result, they can achieve a balanced supply chain that meets customer expectations without unnecessary surplus inventory.

The first step in optimizing safety stock levels is understanding demand variability. Analyzing historical sales data allows businesses to identify patterns in customer behavior and seasonality. This historical data serves as a foundation for forecasting future demand, helping organizations determine when inventory must be increased or decreased. Using techniques such as moving averages and exponential smoothing, companies can create more accurate demand forecasts. In addition, businesses can integrate external factors, such as market trends and economic indicators, to further enhance their forecasting accuracy. Moreover, collaboration with suppliers and partners can help organizations gather relevant information about anticipated demand changes. This collaborative approach leads to better alignment across the supply chain, ultimately optimizing safety stock levels. By employing advanced analytics, businesses can also simulate various demand scenarios to understand their potential impact on inventory levels. This understanding enables companies to make informed decisions about their safety stock levels, reducing the risks of stockouts and overstocks. Ultimately, investing time and resources into understanding demand variability will yield substantial benefits for companies navigating supply chain uncertainties.

Strategies for Managing Demand Variability

Effective strategies for managing demand variability can significantly enhance safety stock optimization. One method involves utilizing the concept of service levels, which indicates the probability of meeting customer demands without encountering stockouts. By determining the desired service level, companies can calculate the appropriate safety stock levels needed to achieve that goal. Additionally, organizations can implement demand-driven planning, which focuses on real-time data to forecast future demand rather than solely relying on historical trends. This approach allows businesses to react swiftly to demand changes, optimizing inventory levels more effectively. Furthermore, engaging in effective communication with stakeholders plays a vital role. This dialogue can facilitate better understanding of market conditions and consumer preferences. As a result, organizations can adjust their inventory management strategies accordingly. Another useful strategy is employing inventory segmentation, which involves categorizing products based on their demand variability. By differentiating products, companies can allocate resources more efficiently, ensuring that high-demand items receive adequate safety stock. All of these strategies contribute to an efficient supply chain, reducing the negative impacts of demand variability.

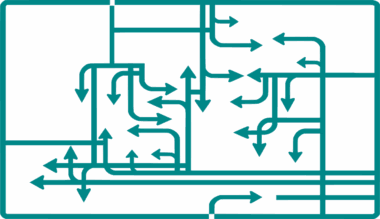

To maintain flexibility amidst demand uncertainty, businesses should consider adopting a responsive supply chain model. This model emphasizes agility by integrating supply chain partners to collaborate effectively, share information, and respond swiftly to fluctuations in demand. Employing a just-in-time (JIT) inventory strategy can also help minimize inventory holding costs while meeting customer expectations promptly. Another key component of operational flexibility is utilizing technology for real-time visibility throughout the supply chain. Through cloud-based systems and IoT, companies can monitor inventory levels, order cycles, and demand trends comprehensively. Real-time data empowers businesses to make timely decisions regarding safety stock inventory adjustments. Implementing demand sensing tools also enables firms to gather insights from market trends and customer behaviors, further enhancing their forecasting capabilities. A combination of technology, collaboration, and strategy can effectively equip companies to handle demand uncertainties while optimizing safety stock levels. As businesses strive for continuous improvement, investing in these tools and strategies will bolster their ability to thrive in a highly competitive marketplace, ensuring they can maintain customer satisfaction and profitability.

The Role of Technology in Safety Stock Optimization

Technology plays an increasingly vital role in optimizing safety stock levels amid demand uncertainty. Advanced forecasting software uses machine learning algorithms to analyze vast datasets, providing insights into demand trends and variability. Such tools enable businesses to simulate various scenarios and evaluate potential outcomes based on historical patterns and real-time data. Furthermore, integrating inventory management systems with demand planning tools enhances responsiveness within the supply chain. Companies can streamline inventory processes, allowing for more effective adjustments to safety stock levels. This integration ensures that everyone involved has access to accurate information, minimizing the risks of stockouts. Similarly, cloud-based solutions facilitate collaboration across supply chain partners, fostering transparency and enhancing communication. Organizations can share critical inventory data effectively, reducing lead times and improving service levels. Additionally, deploying analytics platforms empowers companies to measure and monitor key performance indicators relevant to their safety stock strategies. By leveraging these technologies, firms can identify inefficiencies, refine their processes, and optimize safety stock levels, ultimately achieving greater supply chain resilience in uncertain market conditions.

Another crucial element for success in optimizing safety stock levels is proper training and education of personnel involved in supply chain operations. Empowering employees with knowledge of best practices in inventory management contributes to making informed decisions related to safety stock. Training programs can cover topics such as demand forecasting techniques, inventory optimization strategies, and the use of relevant technology tools. Additionally, fostering a culture of continuous improvement encourages employees to assess and enhance safety stock-related processes regularly. Cross-functional collaboration between departments, including sales, marketing, and logistics, is essential for integrating different perspectives on demand variability. This holistic approach ensures that all areas of the business work together to achieve effective inventory management. Furthermore, organizations should regularly review and analyze their safety stock strategies, utilizing insights gained from data analytics and employee feedback. By implementing such ongoing reviews, companies can adapt to the evolving market landscape and align their safety stock levels with current demand conditions. Ultimately, investing in employee training and cross-department collaboration leads to more accurate forecasting and enhanced overall supply chain performance.

Balancing Cost and Service Levels

When optimizing safety stock levels, companies must strike a delicate balance between cost and service levels. While maintaining high service levels is crucial for customer satisfaction, excessive safety stock can lead to increased carrying costs and reduced profitability. Therefore, it is essential to calculate the optimal safety stock that aligns with business goals while minimizing costs. Implementing a cost-benefit analysis allows organizations to evaluate the trade-offs between holding safety stock and the potential lost sales from stockouts. Additionally, businesses should consider segmenting inventory based on demand variability and profitability, which will help identify which products require higher safety stock levels. Prioritizing and optimizing high-impact items ensures that investments in safety stock yield returns aligned with organizational objectives. Furthermore, organizations can explore vendor-managed inventory (VMI) arrangements, where suppliers manage stock levels, reducing the burden on internal resources. By fostering strong relationships with suppliers, companies can enhance their replenishment processes, allowing for better alignment between inventory levels and customer demand. Overall, careful planning and analysis can lead to efficient safety stock management, balancing costs and service expectations.

In conclusion, effectively optimizing safety stock levels amidst demand uncertainty is vital for successful supply chain management. Businesses must personalize their approaches by leveraging data-driven insights, advanced technology, and collaborative strategies to navigate the complexities of demand variability. By understanding demand patterns and employing effective forecasting techniques, organizations can accurately determine the appropriate safety stock levels. Investing in employee training and cultivating a culture of continuous improvement will further enhance the organization’s ability to respond to market changes. Companies must also weigh the costs and benefits of maintaining safety stock while ensuring high service levels. By striking this balance, businesses can achieve greater profitability and customer satisfaction, enhancing their competitive edge. Moreover, conducting regular reviews and adapting strategies according to changing market conditions are vital for continued success. Effective communication and collaboration with supply chain partners also play a crucial role in optimizing safety stock levels. Ultimately, embracing these practices will lead to a more resilient and responsive supply chain, empowering organizations to meet customer demands while managing costs effectively and ensuring long-term growth.