The Role of Collaboration in Achieving Supply Chain Visibility

In today’s complex business environment, achieving supply chain visibility hinges significantly on collaboration among various stakeholders. Effective communication ensures that all parties are informed of stakeholder requirements and can respond promptly. Enhanced collaboration leads to better alignment of supply chain processes and shared information across the board. This shared understanding cultivates trust among all partners, including suppliers, manufacturers, and distributors. Additionally, implementing collaborative tools such as cloud-based platforms promotes real-time data sharing, enabling stakeholders to monitor inventory levels and order status seamlessly. Strong collaboration practices yield the ability to respond rapidly to disruptions, thus minimizing delays and potential losses. Companies can leverage advanced analytics and shared data to make informed decisions in adverse conditions. A collaborative approach also helps identify opportunities for cost reduction and efficiency improvements. As businesses move towards global supply chains, the importance of inter-organizational collaboration becomes even more pronounced. By fostering a culture of cooperation and communication, organizations can overcome barriers to visibility and create a more resilient, agile supply chain that ultimately enhances overall performance and profitability.

Collaboration can also bridge the information gap that often exists in supply chains. Traditional supply chain models often maintain information silos, leading to inefficient operations. By breaking down these barriers, companies can achieve a unified view of operations that incorporates insights from all partners. Such transparency is essential for avoiding stockouts and reducing excess inventory. When stakeholders collaborate closely, they can synchronize production and distribution schedules effectively to ensure that products are available when needed. Implementing best practices requires commitment from every partner involved in the supply chain—from procurement to delivery. This commitment often translates into strategic partnerships where everyone works towards shared goals, fostering a win-win scenario. Additionally, collaboration can accelerate problem-solving processes, enabling quicker responses to unforeseen challenges. Emphasizing joint responsibility allows all parties to take ownership of their roles. As organizations cultivate these partnerships, mutual benefits arise, strengthening the overall supply chain structure. Therefore, businesses looking to enhance their supply chain visibility should prioritize strategic collaboration as part of their operational strategy, as it brings significant advantages that lead to long-term sustainability.

Technology’s Role in Collaborative Visibility

Technological advancements have revolutionized the way supply chain stakeholders collaborate. Through platforms that facilitate data exchange, companies can ensure timely access to critical information. Tools such as Enterprise Resource Planning (ERP) software and Supply Chain Management (SCM) solutions enable stakeholders to share real-time updates on inventory, shipments, and production status. By integrating these technologies, organizations can automate data gathering and reduce the potential for errors. Moreover, technologies such as Artificial Intelligence (AI) and Machine Learning (ML) can analyze vast amounts of data, providing valuable insights to enhance decision-making. These technological solutions create opportunities for predictive analytics, allowing businesses to forecast demands accurately and adapt their strategies accordingly. Additionally, mobile applications enhance collaboration by enabling on-the-go access to vital supply chain information. This ensures that all stakeholders remain informed and can take swift action when necessary. The importance of adopting these technologies cannot be overstated, as they form the backbone of a collaborative framework that enhances visibility throughout the supply chain. Investing in such technologies leads to not only improved operations but also better customer satisfaction through consistent delivery and service reliability.

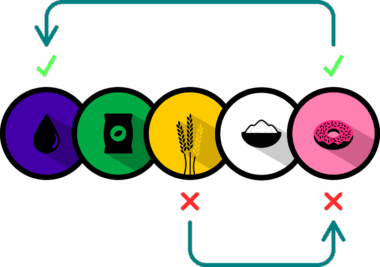

Incorporating collaborative practices into supply chain management leads to significant improvements in overall efficiency. For instance, by working closely with suppliers, organizations can optimize production schedules, resulting in reduced lead times and costs. Enhanced collaboration fosters deeper relationships, encouraging suppliers to prioritize reliability, quality, and timely delivery. Proximity to suppliers is also crucial; collaborating with local suppliers can lead to shorter delivery times and improved communication. In conjunction with this, sharing forecasts and production plans allows suppliers to align their processes with customer expectations effectively. Achieving this level of coordination ensures that materials and goods are available precisely when needed, thus minimizing waste and enhancing flow. Additionally, collaborative logistics can significantly lower transportation costs by optimizing routes and capacities. This often involves joint transportation initiatives among stakeholders, leading to shared freight costs and reduced carbon footprints. Therefore, organizations that actively embrace collaborative practices gain distinct advantages, allowing them to stay agile and competitive in a rapidly changing market. This alignment translates into a better capacity for response to unforeseen challenges, ensuring overall stability and continuity in supply chain operations.

Challenges to Achieving Collaborative Visibility

Despite the clear benefits of collaboration in achieving supply chain visibility, challenges do arise. Organizations may face resistance to change from partners unaccustomed to sharing information. Trust issues can inhibit the flow of necessary data, leading to missed opportunities for improvement. Additionally, discrepancies in systems and technologies can hinder seamless collaboration, as not all stakeholders may utilize compatible tools. These complexities often require organizations to invest in training and infrastructure, which can be seen as a burden. Balancing the need for transparency with confidentiality is also a tricky aspect of collaboration. Companies must ensure that sensitive information is adequately protected while still promoting openness. Furthermore, global supply chains introduce added layers of complexity involving time zones, regulations, and cultural differences. Such factors can complicate communication efforts among international partners. To overcome these obstacles, developing trust-based relationships is essential, along with aligning goals and objectives. While the initial process may be challenging, patience and commitment from all involved can yield substantial benefits. Therefore, addressing these challenges head-on is crucial for organizations aiming to harness the power of collaboration for enhanced supply chain visibility.

Measuring the success of collaborative efforts is vital for continuous improvement in supply chain visibility. Organizations must establish key performance indicators (KPIs) that reflect the effectiveness of collaborations. Metrics can include lead times, order accuracy, inventory turnover, and customer satisfaction scores. By regularly monitoring these metrics, businesses can identify areas for enhancement and gauge the impact of collaborative initiatives. Collaboratively defining these KPIs with stakeholders promotes shared accountability and motivates each partner to contribute actively towards improvement goals. Furthermore, businesses can conduct regular reviews to analyze performance and adjust strategies as necessary. Engaging in feedback loops allows all parties to express concerns and share insights, fostering a culture of continuous improvement. Investing in training and development programs can also boost collaborative efforts, as well-trained staff members are better equipped to respond to evolving challenges. Employing collaboration tools that provide real-time data analytics enhances the ability to track performance. By focusing on measurable outcomes from partnerships, organizations can ensure that their collaborative efforts translate into tangible benefits. The continuous pursuit of excellence in collaboration can markedly elevate overall supply chain visibility and operational agility.

Conclusion: Emphasizing Collaborative Culture

In conclusion, the role of collaboration in achieving supply chain visibility cannot be overstressed. Organizations must cultivate a collaborative culture that prioritizes communication, transparency, and mutual respect among all stakeholders. Emphasizing the importance of shared objectives strengthens relationships and aligns efforts towards common goals. This culture encourages team members to engage actively and seek innovative solutions to challenges. Moreover, businesses should leverage technology to facilitate collaboration, ensuring relevant stakeholders can access critical information at all times. Establishing clear protocols regarding data sharing and decision-making can further enhance the collaborative spirit. Organizations that prioritize collaboration not only achieve better visibility in their operations but also foster resilience against disruptions. By building trust and confidence among stakeholders, companies can navigate the complexities of modern supply chains more effectively. Therefore, integrating collaboration strategies into the core of supply chain management is essential. Ultimately, a strong collaborative framework provides a significant competitive advantage by enhancing responsiveness and agility. Businesses that focus on developing a collaborative culture can set themselves up for long-term success in the ever-evolving landscape of supply chain management.

As we look to the future, it is evident that supply chain visibility will continue to rely heavily on collaborative efforts. The ongoing global disruptions exemplified by recent events highlight the need for robust communication channels and agile strategies. Companies must also consider the implications of sustainability within their collaborative frameworks. Building a sustainable supply chain requires input and commitment from everyone within the network. Initiatives such as green logistics and waste reduction efforts increasingly leverage collaborative approaches to achieve their goals. With advancements in technology, organizations can take collaboration to new heights, implementing predictive analytics and blockchain solutions to enhance transparency. The future of supply chain visibility hinges not only on technology but on the relationships forged through collaboration. As organizations adapt to new market realities, they can only thrive by fostering inclusive, cooperative relationships with all partners involved. The integration of collaborative practices will likely give rise to innovative solutions and practices that could redefine supply chains globally. Ultimately, pursuing collaboration and continuously enhancing visibility are crucial for building resilient supply chains that meet evolving customer demands and expectations.