The Role of Automation in Inbound Logistics Processes

Inbound logistics is a critical component in the supply chain management, directly impacting efficiency and cost-effectiveness. Automation in this realm significantly streamlines processes, facilitating a faster and more accurate flow of goods. By integrating automated systems, businesses can minimize manual handling, reducing errors and improving productivity. Automated ordering systems, for instance, can alert suppliers when stock levels reach predetermined thresholds, ensuring timely replenishment. Furthermore, technologies such as barcode scanning and RFID tracking allow for real-time inventory updates, offering exceptional visibility into stock levels and locations. These technologies not only enhance accuracy but also enable better decision-making. Companies leveraging automation in inbound logistics are often able to respond dynamically to market demands, thus improving customer satisfaction. Moreover, this efficiency can lead to reduced operational costs as less labor is required for manual tasks. Moving forward, organizations should prioritize investing in automation technologies as part of their inbound logistics strategy to remain competitive. Embracing these advancements can ensure a more cohesive and responsive supply chain, ultimately benefiting both the organization and its clientele.

Automation means utilizing various technologies to improve efficiency, accuracy, and speed in inbound logistics. This can include software for tracking shipments and managing inventory, as well as automated machinery for sorting and handling goods. The benefits of automation are vast; for instance, automated systems can help in reducing lead times by swiftly processing incoming shipments. Additionally, safety is significantly enhanced, as automation can replace hazardous manual tasks, thereby protecting employees. With reduced reliance on human labor, organizations can also mitigate risks associated with human errors. Technological advancements in robotics have further transformed inbound logistics, enabling processes that deal with large volumes of goods to be executed smoothly. Moreover, real-time data analytics empowers businesses to optimize their logistics operations continually. By generating actionable insights from past performance, stakeholders can make informed decisions that drive efficiency in inbound logistics. Automation streamlines these operations, providing comprehensive visibility throughout the logistics process. Companies should consider the unique needs of their operations while implementing automation to reap maximum benefits, ensuring that every aspect is aligned with their strategic goals.

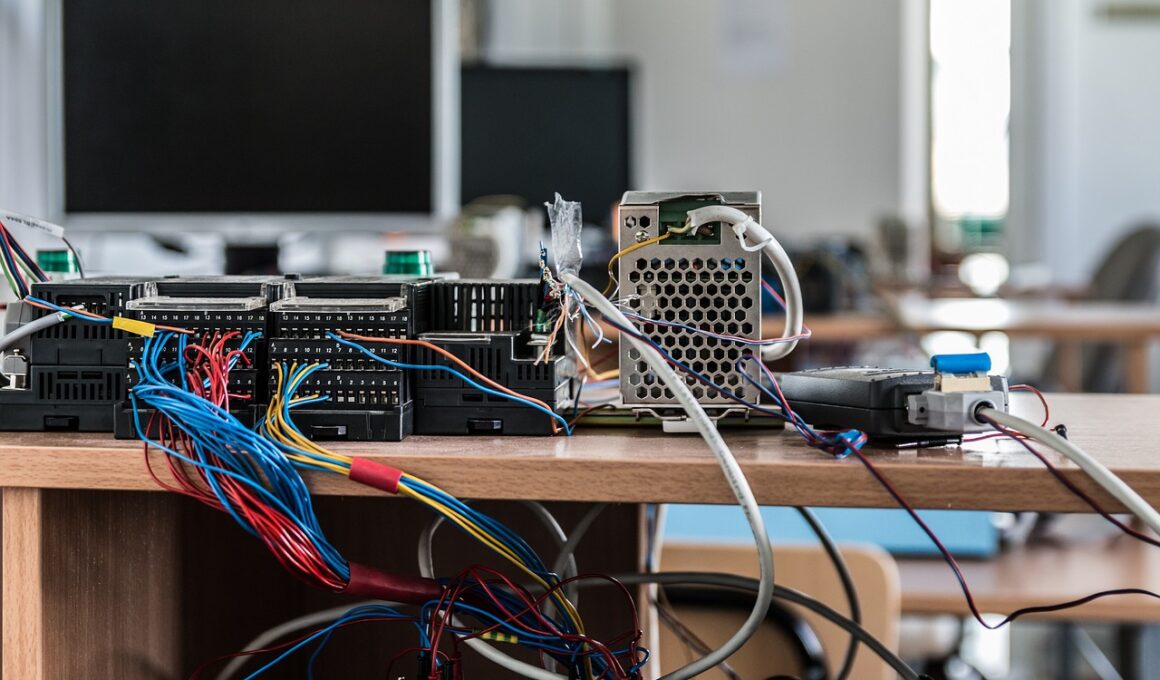

Technologies Driving Automation

Several technologies are at the forefront of automating inbound logistics processes, revolutionizing how organizations operate. Robotics is one key technology that enhances the movement and sorting of goods within warehouses. These robots can autonomously transport materials, eliminating the need for manual labor and allowing employees to focus on higher-value tasks. Additionally, artificial intelligence enables predictive analytics, helping businesses forecast demand and optimize inventory levels. Predictive maintenance powered by AI can also reduce downtime by identifying equipment issues before they escalate. Furthermore, warehouse management systems (WMS) integrated with automation technology provide end-to-end visibility. They streamline workload distribution, ensuring tasks are completed efficiently. Cloud computing enhances collaboration by allowing real-time data access among stakeholders, aiding in decision-making processes. Automated guided vehicles (AGVs) are increasingly becoming commonplace within warehouses, enhancing material handling operations. These technologies collectively create a more agile logistics environment, positioning companies for sustainable growth. As the logistics industry evolves, staying updated with these technological advancements will be crucial. Businesses must recognize that investing in these innovations can yield significant returns, enhancing their overall operational efficiency.

Investing in automation is essential for maximizing efficiency in inbound logistics processes. However, organizations must carefully consider the associated costs and benefits before implementation. Initial investment costs in advanced technologies can be significant, but these costs often pale in comparison to the long-term savings realized through improved efficiencies. Reducing labor costs, minimizing errors, and streamlining operations can contribute directly to increased profit margins. Moreover, organizations can explore financing options that may offset upfront costs while still enabling them to leverage the benefits of automation. Training existing staff to operate new technologies is also key to successful implementation. Empowering workers with the skills necessary to manage automated systems ensures that operations run smoothly post-deployment. Organizations should assess their current processes to identify specific areas where automation can make the most impact. Implementing incremental automation may be a viable strategy for businesses hesitant to go all-in. By gradually integrating automation into their logistics processes, companies can witness immediate improvements while avoiding overwhelming changes that may disrupt operations. Ultimately, the approach taken will determine how effectively automation enhances inbound logistics.

Impact on Workforce

The rise of automation in inbound logistics inevitably impacts the workforce. As routine tasks become automated, roles within organizations are shifting. While there are concerns about job displacement, automation often leads to the creation of new job opportunities. Employees are needed to manage, maintain, and optimize automated systems, thus requiring new skill sets. Upskilling workers can transform the workforce, providing them with opportunities to grow in their careers. Logistics companies focusing on this aspect can foster a more capable, adaptable workforce ready to take on advanced technological challenges. Communication is crucial when introducing automation; ensuring employees understand how these changes will positively impact the organization can alleviate tensions. Additionally, incorporating employee feedback during the transition to automated systems can enhance overall job satisfaction and productivity. Employee engagement will play a significant role in determining the success of automation initiatives. Organizations should prioritize fostering a culture that values learning and adaptation as they introduce automation. This approach can motivate workers and encourage them to see automation as a tool that enhances their roles rather than a threat to job security.

Despite the numerous advantages of automation in inbound logistics, organizations must remain aware of potential challenges. Integrating new technologies can face resistance from employees who may fear job loss or change. It is essential for management to communicate clearly about the reasons behind automation initiatives, outlining the benefits not only for the company but also for employees. Additionally, ensuring there is adequate training available can ease concerns and help staff transition smoothly to automated operations. Cybersecurity is another pressing issue; as organizations automate, they increase their exposure to digital threats. Implementing robust cybersecurity measures is paramount to protect sensitive information and maintain the integrity of operations. Furthermore, the integration of various systems can present compatibility issues, demanding a structured approach to technology adoption. Continuous evaluation and monitoring of automated systems are necessary to ensure they operate as intended. By proactively addressing these challenges, organizations can maximize the potential benefits of automation in inbound logistics. Companies that navigate these complexities effectively will position themselves as leaders in the logistics sector, setting new benchmarks for operational excellence.

Future of Inbound Logistics

As we look to the future, automation will undoubtedly play a pivotal role in shaping inbound logistics. The ongoing development of technologies such as machine learning and the Internet of Things (IoT) will further enhance operations. IoT-enabled devices can provide real-time tracking of shipments, delivering unprecedented visibility and control. This data-driven decision-making will enable organizations to become more agile and responsive to changing needs. Collaborations between manufacturers, suppliers, and logistics providers will increasingly rely on automated solutions, creating a more integrated supply chain. The future will also witness a greater focus on sustainability influenced by automated systems that optimize resource utilization. Companies prioritizing eco-friendly practices through automation will not only fulfill regulatory requirements but also appeal to environmentally conscious consumers. Additionally, a rising interest in blockchain technology promises to enhance transparency and traceability across logistics operations. Automation will need to evolve continuously as technological advancements emerge, driving further enhancements in speed and efficiency. Embracing future trends will be essential for organizations aiming to maintain a competitive advantage within a rapidly changing logistics landscape.

In conclusion, automation is reshaping the inbound logistics landscape, offering significant improvements in efficiency, accuracy, and responsiveness. With technologies continually evolving, understanding their implications for inbound logistics is essential for organizations to thrive. As businesses effectively integrate automated systems, they can unlock the potential for growth and success. Investing in the right automation tools and technologies will ultimately lead to optimized processes, reduced costs, and improved customer experiences. The key lies in recognizing that automation is not merely a trend; it’s a fundamental shift in how logistics processes operate. Forward-thinking companies will prioritize embracing these changes, ensuring they stay ahead of the competition. Moreover, addressing employee concerns, providing adequate training, and fostering a culture of learning will be equally important as organizations navigate this transition. The future of inbound logistics promises to be dynamic, with automation paving the way for innovative solutions that improve overall operational resilience. Companies will need to be with adaptable strategies as they leverage automation to build more efficient supply chains. By doing so, they position themselves not just for survival, but for long-term success in a complex, interconnected world.