Data Mining Techniques for Supply Chain Optimization

Data mining techniques play a crucial role in optimizing supply chains, significantly enhancing efficiency and reducing costs. By extracting valuable insights from data, businesses can make informed decisions that directly impact their supply chain operations. These techniques analyze large datasets to identify trends, patterns, and relationships among various supply chain variables. For instance, predictive modeling can be utilized for demand forecasting, allowing companies to align inventory levels effectively. This alignment minimizes excess stock and shortages, leading to cost savings and improved customer satisfaction. Additionally, clustering techniques can group similar suppliers or customers, enabling a more tailored approach in procurement and service delivery. Organizations are thus empowered to respond dynamically to market changes, fostering agility in operations. Implementing these data-driven strategies can transform traditional supply chain models into more proactive and responsive frameworks. Hence, investing in data mining capabilities is essential for companies looking to maintain competitive advantages in today’s fast-paced business environment. As industries continue to embrace digital transformation, understanding and applying data mining techniques effectively will be paramount for supply chain optimization.

Machine learning algorithms have emerged as vital tools in the context of supply chain analytics. These algorithms enable businesses to forecast demand forecasts with greater accuracy by analyzing historical data patterns. For example, regression analysis can predict future sales based on seasonality or promotional activities. Furthermore, classification algorithms can help the organization categorize products based on performance metrics, assisting in inventory management. The ability to segment customers through insights gained from data analysis enhances targeted marketing strategies. It leads to improved customer relationships and product offerings. In addition to demand forecasting, machine learning can enhance logistics optimization. Algorithms can assess traffic patterns and transportation routes to find the most efficient delivery routes. Consequently, this optimizes delivery times and minimizes transportation costs. Another key benefit of integrating machine learning into supply chains is the reduced risk of stockouts and overstocks. By knowing product demand trends, businesses can manage their inventories more effectively. Thus, businesses leveraging machine learning within their supply chain analytics pave the way for more streamlined operations and strategic decision-making.

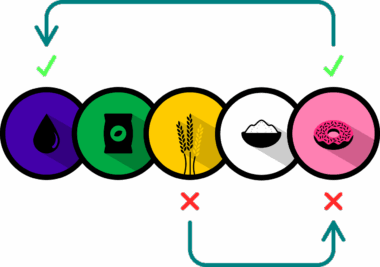

Clustering and Classification Approaches

Clustering and classification approaches in supply chain analytics are transformative, enabling companies to gain deeper insights into their operations. Clustering algorithms help categorize suppliers, products, or transport routes based on specific attributes, revealing patterns that may not be evident with traditional analysis. For instance, K-means clustering is frequently used for customer segmentation, whereby similar purchasing behaviors are grouped together. This segmentation allows for targeted marketing initiatives and optimized inventory strategies tailored to different customer needs. On the other hand, classification techniques, such as decision trees and random forests, provide valuable predictive power. These methods assess various factors influencing supply chain performance, improving decision-making quality. By understanding which variables impact the efficiency and effectiveness of operations, businesses can make proactive adjustments. Furthermore, utilizing clustering and classification can aid in risk management, accounting for potential disruptions in the supply chain. Organizations can identify high-risk areas and implement contingency plans to mitigate impacts. Employing these analytical approaches ensures a comprehensive understanding of both operational strengths and weaknesses within the supply chain.

Text mining is an underutilized data mining technique in supply chain analytics that holds significant potential. It focuses on extracting valuable information from textual data sources such as customer feedback, social media, and supplier communications. Text mining can unveil insights regarding customer preferences, emerging market trends, and potential issues within the supply chain. For instance, analyzing customer reviews can help identify common pain points associated with product quality or delivery times, enabling organizations to rectify these issues. Additionally, examining social media discussions can reveal customer sentiments towards brands and products, allowing companies to adapt their strategies accordingly. This proactive approach to understanding consumer sentiment can enhance product offerings and customer satisfaction levels. Moreover, text mining can aid in supplier selection processes by analyzing supplier performance records, ensuring organizations partner with reliable vendors. As supply chains become increasingly interconnected and data-intensive, harnessing the power of text mining will become imperative for organizations striving for competitive advantage. In conclusion, companies should recognize the immense value in their unstructured data and employ text mining techniques accordingly.

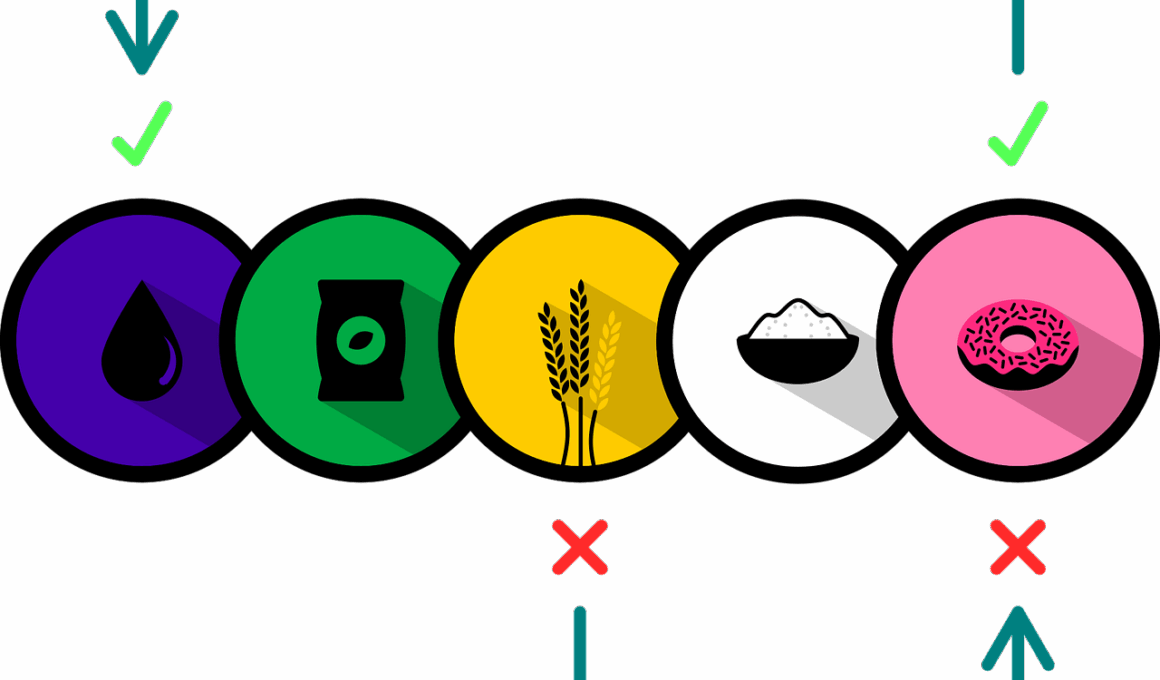

Visualization Techniques

Effective communication of data insights is essential for driving informed decisions in supply chain management. Visualization techniques play a vital role in transforming complex data into intuitive graphical representations. Dashboards, heat maps, and graphs are just a few examples of visualization tools employed in supply chain analytics. By visualizing data, stakeholders can quickly identify trends, outliers, and areas requiring attention. For instance, heat maps can illustrate inventory levels across different locations, allowing managers to pinpoint regions with shortages or overstock situations instantly. Additionally, graphical representations of transportation costs over time can reveal fluctuations that require strategic interventions. Another significant benefit of data visualization is simplifying communication between departments. With easily interpretable visuals, decision-makers from different teams can share insights collaboratively, enhancing cross-functional understanding. As a result, this fosters cohesive decision-making and strategic alignment. Moreover, organizations can leverage advanced visualization techniques like interactive dashboards that allow users to drill down into specific data points for deeper analysis. Investing in robust visualization capabilities thus strengthens supply chain communication and fosters an analytics-driven culture.

Integration of Internet of Things (IoT) with supply chain analytics enhances real-time decision-making and operational responsiveness. IoT devices generate massive amounts of data from various touchpoints, including sensors in warehouses, transport vehicles, and even products themselves. Through continuous monitoring, companies can gain insights into product conditions, locations, and supply chain performance. For instance, temperature-sensitive products can be tracked through IoT sensors to ensure they are transported and stored appropriately. Utilizing these insights allows organizations to identify potential issues before they escalate, preserving product quality and minimizing waste. Furthermore, IoT integration can lead to smarter inventory management, as real-time data provides clarity on stock levels. When combined with predictive analytics, businesses can anticipate inventory needs, allowing them to respond swiftly to fluctuations in demand. An IoT-driven approach promotes greater visibility across the supply chain, enhancing collaboration between stakeholders. Additionally, leveraging analytics with IoT data can uncover inefficiencies and bottlenecks, providing a foundation for continuous improvement. The synergy of IoT and analytics builds resilient supply chains prepared to adapt to market dynamics.

Conclusion and Future Directions

The future of supply chain optimization hinges on expanding the use of data mining techniques for comprehensive analytics. As technology continues to evolve, organizations must adapt by embracing advanced analytical capabilities to stay competitive. The potential of artificial intelligence and machine learning in analyzing vast datasets will further enhance supply chain processes. Consequently, businesses should invest in training their workforce to effectively leverage these technologies and foster a data-driven culture. Moreover, increasing collaboration between departments driven by analytics will facilitate more strategic decision-making and holistic optimization of supply chains. Exploring advanced data mining methods, such as deep learning, can also provide more sophisticated insights into supply chain performance. As supply chains navigate the complexities of global markets and consumer demands, prioritizing data-driven decision-making will be a game-changer. Organizations that successfully harness the power of data mining will optimize their operations, leading to increased efficiency and customer satisfaction. In conclusion, the insights gained from data mining are invaluable for shaping resilient, agile, and intelligent supply chains in the future.