Real-Time Inventory Monitoring Using Automated Tools

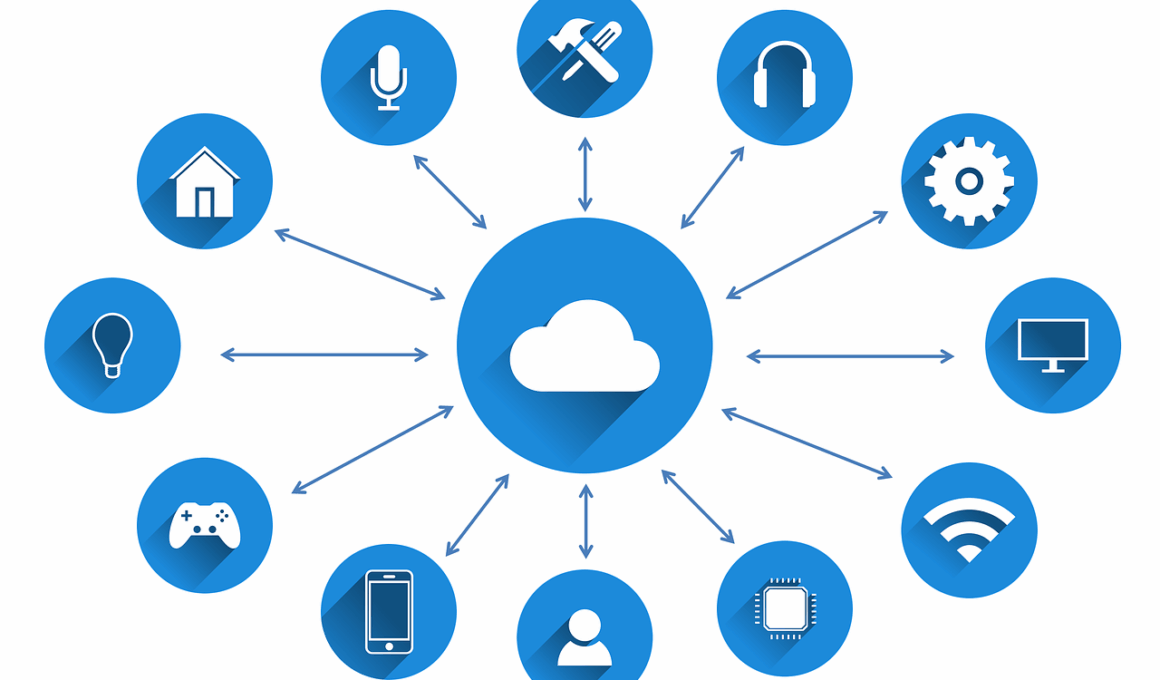

In today’s fast-paced business environment, effective inventory management is essential for operational success. Automated tools are increasingly vital for maintaining accurate, real-time visibility into inventory levels. Businesses using these systems can promptly identify discrepancies, minimize stockouts, and maximize efficiency. With real-time inventory monitoring, organizations can leverage advanced technologies such as RFID and barcode scanning for better tracking. These automated solutions enable businesses to optimize space, reduce overhead costs, and make informed purchasing decisions. Furthermore, integrating inventory management systems with other business applications increases synergy across departments, ultimately enhancing decision-making capabilities. Embracing automation bolsters supply chain efficiency and supports scalability for future growth. A sound inventory strategy significantly enhances customer satisfaction by ensuring products remain available when needed. Adopting these automated tools not only benefits businesses but cultivates a forward-thinking, adaptable corporate culture. Ultimately, the use of real-time monitoring systems significantly influences the competitive landscape, providing a solid foundation for sustainable growth and profitability. The future of inventory management relies on innovative solutions that streamline processes and foster resilience in an evolving market.

The integration of automated inventory monitoring tools drastically enhances tracking accuracy and speed. Manual inventory methods are often prone to human error, leading to miscalculations and outdated data. Automated systems, however, utilize technology to ensure that inventory records are up-to-date, effectively reducing discrepancies. As products move through the supply chain, automated tools capture and process information instantly, allowing businesses to respond to changes dynamically. This real-time approach to inventory management enhances operational efficiency, saving organizations both time and money. Moreover, companies can analyze trends and identify critical stock levels through integrated reporting functionalities. Automated inventory systems provide insights into the most demanding products, helping businesses execute better-informed purchasing decisions, reducing excess inventory. By implementing these tools, companies significantly lower the risk of stockouts and overstock situations. The ability to access real-time data facilitates strategically aligned inventory practices, positively impacting customer service. Automated inventory management helps businesses understand their supply dynamics and supports just-in-time inventory strategies. As a result, organizations can create streamlined operations that ultimately bolster competitive advantages in the marketplace and enhance profitability.

Benefits of Real-Time Inventory Monitoring

Real-time inventory monitoring offers a multitude of benefits that contribute to organizational effectiveness. First, businesses achieve heightened accuracy in tracking stock levels, which is crucial for effective planning. Using automated tools, inaccuracies associated with manual entry are minimized, ensuring that decision-makers have access to reliable information. In addition, organizations can closely monitor inventory turnover rates, leading to informed strategic adjustments when necessary. Cost savings is another critical advantage. By optimizing stock levels, businesses reduce carrying costs associated with excess inventory that ties up capital. Automation enables swift response times to replenishment needs, so inventory aligns with current demand. Furthermore, effective monitoring facilitates improved supplier relationships, as businesses can provide consistent orders based on precise demand forecasting. The end result means a more resilient supply chain, capable of meeting fluctuations in market conditions. Enhancing customer satisfaction becomes simpler with real-time visibility into inventory. Customers can expect enhanced service, as businesses can fulfill orders promptly, thus fostering loyalty and repeat business. Overall, implementing real-time inventory monitoring results in robust organizational performance and crucial advantages over competitors.

Automated inventory management systems are built on advanced technologies that significantly improve workflow efficiency. By eliminating time-consuming manual processes, organizations can redirect their resources toward core functions and growth initiatives. The integration of technologies such as artificial intelligence and machine learning allows businesses to forecast demand accurately, improving inventory planning. Automated tools can analyze historical sales data, seasonality effects, and market trends, equipping decision-makers with actionable insights. Businesses leveraging such innovations gain a competitive edge by adapting their inventory strategies to evolving consumer preferences. Furthermore, automation mitigates risks associated with stockouts, bolstering customer satisfaction. Automating notifications and alerts for low inventory levels can trigger timely stock replenishment, ensuring product availability. As organizations increasingly respond to market dynamics, manual systems fall short, rendering them less effective. Therefore, embracing automation is essential for businesses seeking survival in a digital-first landscape. Investing in automated inventory solutions is not merely a trend but a strategic necessity for long-term success. Ultimately, these systems support increased revenue generating opportunities while allowing businesses to stay ahead of competitors navigating similar challenges.

Challenges in Implementing Automated Tools

While the advantages of real-time inventory monitoring are manifold, businesses may encounter challenges during the implementation of automated tools. Initial setup costs for these systems can be substantial, potentially deterring smaller organizations from adopting such technology. Additionally, businesses must ensure proper integration with existing infrastructure and applications, which may require investment in training and change management initiatives. Furthermore, resistance to change from employees can pose significant hurdles. Reassuring the workforce about the benefits of automation and providing adequate training is crucial for smooth transitions. Businesses also face pitfalls during data migration, where historical records must be transferred accurately to new systems. Poor-quality data can hinder analysis and affect supply chain decisions adversely. Ongoing maintenance and updates are additional considerations that organizations must navigate, requiring dedicated IT support to keep systems functioning optimally. Adapting to advancements in technology remains a constant challenge, and businesses need strategies in place for continuous improvement. Overcoming these obstacles necessitates a clear strategy and commitment to quality, paving the way for successful implementation and long-lasting benefits.

As businesses embrace the future, the role of real-time inventory monitoring within operational strategies will become increasingly significant. Organizations must assess their current systems and identify gaps in technology that automation can fill. As competitors increasingly leverage automated tools, businesses that fail to adapt could risk losing their market edge. The continuous evolution of technology will drive innovations in inventory management that redefine best practices. Companies must remain agile to respond to emerging trends and technologies. Trusting automated systems enhances real-time decision-making capabilities and operational efficiencies. Integration with eCommerce platforms and point-of-sale systems strengthens inventory management processes, resulting in unified operations that benefit the entire organization. Embracing an omnichannel approach in inventory management ensures that businesses meet their customers’ evolving needs efficiently. Additionally, sustainability will become a key focus, with automated tools supporting data analysis that leads to environmentally friendly practices. As organizations navigate changing market conditions, real-time inventory monitoring will offer unparalleled levels of transparency, enabling firms to respond proactively to shifting consumer demands. The future hinges on harnessing technology that transforms inventory management processes, ultimately setting the stage for sustainable growth and profitability.

Conclusion

In conclusion, real-time inventory monitoring using automated tools is indispensable for businesses striving to enhance efficiency and responsiveness. With the integration of smart technologies, companies gain unparalleled insights into their inventory, resulting in informed decision-making. The benefits extend beyond mere stock management; they influence customer satisfaction and operational effectiveness. Businesses that embrace automation position themselves as leaders within their respective industries, leveraging innovative strategies for sustained growth. However, a successful transition entails addressing challenges like initial setup costs and employee resistance to change. Thus, implementing a solid strategy for adoption is crucial. As organizations plan for expansion, staying abreast of technological advancements helps them to refine or reinvent inventory practices. Ultimately, the future of inventory management depends on adopting technologies that enable companies to thrive amidst constant change. Automation is not merely an option; it’s a necessity that organizations must prioritize to succeed in a competitive landscape. Moving forward, businesses will benefit tremendously by focusing on improving their inventory management acumen and employing real-time monitoring as a backbone for operational excellence.

This article highlights the critical role of real-time inventory monitoring in today’s business landscape. By using automated tools, companies can achieve remarkable improvements in accuracy, efficiency, and strategic flexibility. As we move forward, it is essential for organizations to evaluate their current practices and invest in technologies that can keep them competitive.