Edge Computing in Manufacturing: Enhancing Efficiency and Quality

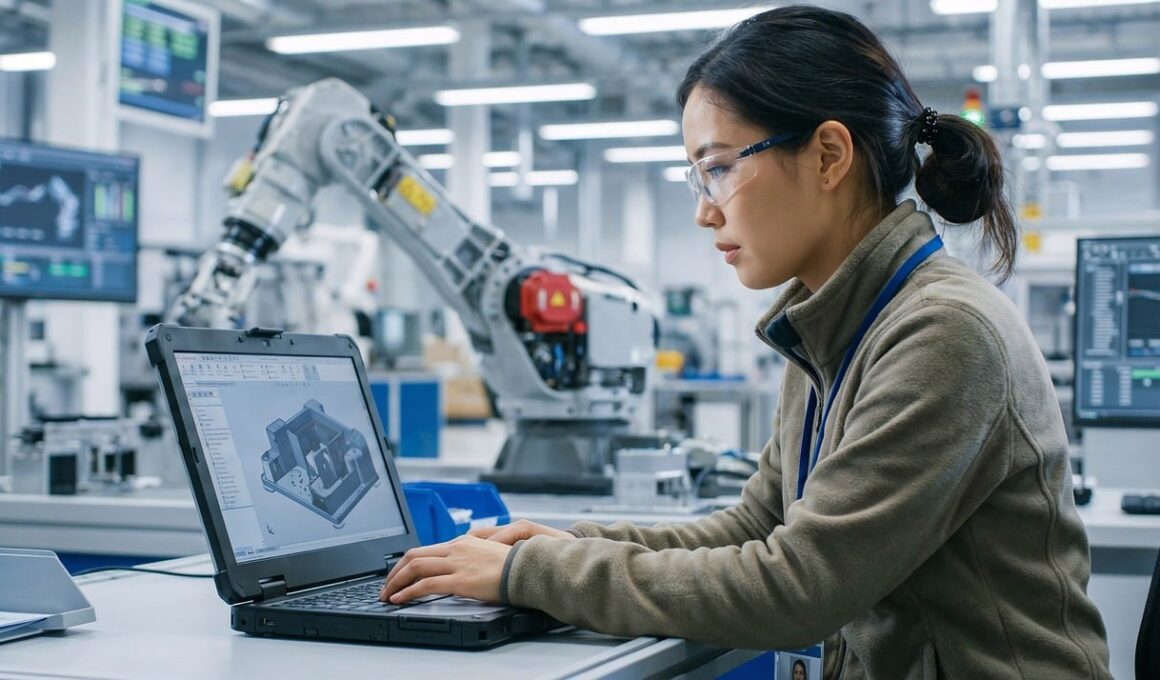

In today’s competitive landscape, edge computing is revolutionizing the manufacturing sector. By processing data closer to where it is generated, manufacturers can achieve stability and speed in operations. This means real-time decision-making capabilities and improved operational efficiency that traditional cloud systems often struggle to provide. Edge computing reduces latency significantly, enabling faster data processing which is crucial for manufacturing processes that rely on precision and timing. Hardware like sensors and IoT devices collect vast amounts of data, which edge devices analyze on-site. Additionally, the reduced volume of data sent to the cloud decreases operational costs. The result is streamlined operations that enhance productivity and promote better quality control.

One of the standout benefits of edge computing in manufacturing is its potential for enhanced quality assurance. In assembly lines, for example, edge devices can immediately analyze data from quality checks, leveraging algorithms to detect defects in products or processes almost instantaneously. This early detection allows for quick interventions, minimizing the cost associated with defective outputs. Additionally, manufacturers can implement predictive maintenance using edge computing. By analyzing equipment performance data in real time, companies can avoid unexpected downtimes and schedule maintenance when it’s most efficient, reducing operational interruptions and increasing overall reliability.

Impact on Supply Chains

Edge computing also impacts supply chain management significantly. By providing greater visibility into real-time operations, edge devices allow manufacturers to track inventory levels, manage logistics, and adapt quickly to changes in demand. Manufacturers can utilize analytics on-site to predict inventory needs. Moreover, integrating edge computing with existing systems offers companies a competitive edge. This streamlined data flow improves communication between suppliers and manufacturers, fostering better collaborations. Consequently, any inefficiencies in the supply chain can be identified and rectified swiftly, leading to a more agile production process.

The integration of edge computing into manufacturing processes promotes not just efficiency but also sustainability. Energy consumption can be reduced as edge devices optimize resource use, contributing to greener practices. For example, by analyzing equipment usage and output efficiency, manufacturers can identify opportunities for energy savings and reduced emissions. Furthermore, by minimizing data travel to centralized systems, energy expenditures related to data processing are significantly lowered. Manufacturing industries are increasingly prioritizing eco-conscious strategies, and edge computing offers a vital solution for addressing sustainability targets while enhancing efficiency.

Challenges in Edge Computing Implementation

Despite its numerous advantages, the transition to edge computing in manufacturing comes with specific challenges. Security concerns are paramount, as more connected devices create more endpoints that are vulnerable to cyber threats. It requires a comprehensive security strategy to address these vulnerabilities effectively. Additionally, integrating edge computing with existing infrastructures may pose complexities that require specialized expertise. Data management strategies must also evolve to accommodate the heightened volume and velocity of data generated locally. Overcoming these challenges will be essential for maximizing the benefits of edge technology in manufacturing.

As manufacturers continue to adopt edge computing, the workforce will need appropriate training to adapt to these technological advancements. Understanding how to leverage real-time data insights for improved decision-making is crucial. Continuous education and reskilling programs will help employees stay ahead in a landscape increasingly dominated by digital technologies. Creating a culture of innovation within the organizational framework will be essential for embracing these changes. The future of manufacturing undoubtedly relies on a harmonious integration of technology and human expertise to optimize processes and outcomes.

Future Trends in Edge Computing

Looking ahead, we can expect further advancements in edge computing that will continue to shape the manufacturing landscape. Emerging technologies, such as artificial intelligence and machine learning, will bolster edge computing capabilities. Enhanced data analytics can lead to more sophisticated insights, driving proactive decision-making in manufacturing operations. Moreover, the combination of 5G technology and edge computing can revolutionize data transmission speeds, enabling real-time analytics and further enhancing operational efficiencies. As these technologies converge, manufacturers will possess unparalleled capabilities to fine-tune output quality and performance metrics.

In conclusion, edge computing stands as a transformative force in manufacturing, affecting operational efficiency and product quality. The seamless integration of edge technology offers manufacturers the agility to respond to market demands and streamline processes considerably. Organizations leveraging edge computing unlock new opportunities for innovation, sustainability, and competitiveness in the rapidly evolving manufacturing sector. To capitalize on these advancements, embracing technology while addressing inherent challenges will be vital for ongoing success in a digitally driven future.