Integration of IoT Devices in Warehouse Logistics Management

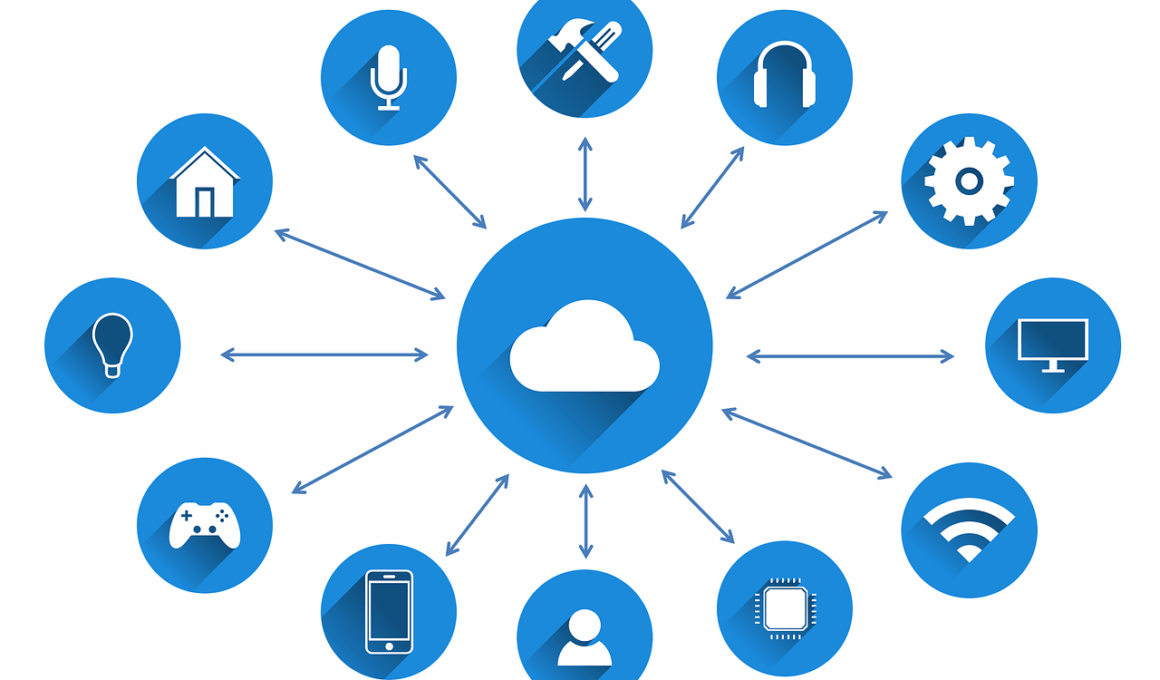

In the modern landscape of warehouse operations, the integration of IoT devices has transformed traditional logistics management. By utilizing internet-connected gadgets, companies can gather real-time data, enhance efficiencies, and significantly reduce operational costs. IoT technology includes sensors, RFID tags, and automated systems that monitor inventory levels, track delivery routes, and optimize picking processes. Understanding the difference between traditional practices and IoT-driven methods can help organizations streamline their operations. With better visibility and control, businesses can respond swiftly to demand fluctuations, ensuring optimal inventory management. These technologies not only improve operational workflows but also contribute to increased customer satisfaction through timely deliveries. However, effectively implementing IoT systems requires strategic planning and investment in infrastructure. Companies must dedicate resources to training staff, ensuring cybersecurity measures, and continuously analyzing data to boost productivity. By embracing IoT, warehouses can not only improve their current operations but also lay the groundwork for future advancements and technology integration, positioning themselves for growth and success in a fast-paced market. As the logistics sector evolves, adapting to these innovations will be essential for staying competitive and responsive in an increasingly digital marketplace.

One of the standout benefits of integrating IoT devices in warehouse logistics management is the increased visibility throughout the supply chain. By employing technologies like RFID and GPS tracking, companies can effectively monitor their assets in real-time. This connectivity allows for a much faster response to any issues that may arise, ultimately leading to reduced delays and enhanced product tracking. For instance, if an item is misplaced or delayed, immediate alerts can be generated, enabling swift remediation actions. Real-time data collection and analytics facilitate better decision-making processes, allowing organizations to refine their operations and improve stock accuracy. Additionally, predictive analytics derived from IoT data can forecast trends and optimize inventory levels, effectively minimizing wastage. This holistic view also contributes to enhancing safety within the warehouse environment as discrepancies can be addressed immediately. Partnering with technology providers specializing in IoT solutions is essential for maximizing these benefits, setting the stage for continuous improvement. Logistics companies must cultivate partnerships with technology innovators to enhance their operational frameworks dramatically. Adopting such strategies ensures better alignment with market needs and fosters resilience in managing fluctuating demands effectively.

Automating Warehouse Processes

Another significant aspect of IoT integration in warehouse management is automation. By employing smart devices, many repetitive and time-consuming tasks can be handled more efficiently. For instance, automated guided vehicles (AGVs) equipped with sensors can navigate the warehouse floor autonomously, picking and transporting goods with minimal human intervention. Implementing such technologies can lead to a significant reduction in labor costs and an increase in throughput. Additionally, automating processes such as inventory counts, order picking, and quality checks allows staff to focus on more complex tasks requiring human judgment and creativity. This leads to improved employee morale and productivity as staff can be redirected to value-adding activities. However, transitioning to an automated environment does entail challenges, such as the need for ongoing maintenance of equipment and technology. Organizations also need to establish a culture of continuous improvement and adaptation to embrace automation fully. The potential benefits of deploying these technologies far outweigh the initial investment and can provide substantial returns over time. Increased efficiency, enhanced accuracy, and cost savings make automation through IoT devices a crucial aspect of modern warehouse logistics management strategies.

Moreover, the integration of IoT technology significantly enhances inventory management practices. With smart shelving systems and RFID tags, companies can accurately monitor stock levels, ensuring products are readily available when needed. This fosters an efficient picking process while also providing valuable data for reordering supplies. When combined with cloud technology, warehouse managers can leverage dashboards displaying all stock information in real-time. This visibility improves communication between departments as all stakeholders can access up-to-date information, ensuring a seamless workflow throughout the organization. An efficient inventory management system minimizes the risk of overstocking or stockouts, safety stock levels can be accurately determined based on real-time data analytics. Additionally, the IoT’s ability to facilitate just-in-time inventory strategies ensures that products are replenished as demand arises, inevitably reducing storage costs. Understanding how to maximize these inventory features through IoT systems will empower businesses to remain lean while delivering high-quality customer service. However, an effective implementation strategy is crucial for successful integration. Logistics managers must engage in proper training, data security protocols, and vendor partnerships to maximize the benefits of this innovative technology.

Enhancing Security and Compliance

Implementing IoT devices effectively can also lead to enhanced security and compliance across warehouse operations. Security threats such as theft can severely undermine a company’s profitability and reputation, making reliable solutions essential. Smart surveillance systems integrated with IoT technology enable real-time monitoring of both warehouse premises and inventory levels, representing a crucial step in tightening security protocols. In addition, these connected devices can facilitate compliance with regulatory guidelines by recording critical data about inventory handling and movement. Such data can be invaluable during audits and inspections, assisting companies in maintaining compliance and avoiding costly penalties. Furthermore, sensors can monitor environmental conditions like temperature or humidity, ensuring that goods are stored under optimal conditions. This is particularly vital for perishables and sensitive items subject to regulatory scrutiny. Investing in comprehensive IoT solutions can significantly reduce risks associated with security breaches and non-compliance. As organizations strive for operational excellence, the focus must be on establishing a robust security and compliance framework, leveraging IoT technologies as an integral component in the logistics management strategy.

In addition to the operational benefits, IoT devices in warehouse management contribute to sustainability efforts. With growing focus on environmental responsibility, companies are increasingly exploring ways to minimize their carbon footprints. IoT technologies allow for better energy management within warehouse facilities, helping organizations identify areas for improvement. Smart energy management systems can track consumption patterns, leading to more informed decisions about resource allocation and efficiency. By optimizing the use of energy, companies not only reduce operational costs but also contribute to sustainability initiatives. Furthermore, reduced waste through better inventory management leads to lower disposal costs and reduced environmental impact. An IoT-integrated warehouse promotes sustainable practices that help organizations meet the growing requirements of both consumers and regulators. Companies can also leverage data to engage in sustainable sourcing, ensuring that their operational choices align with broader environmental goals. Partnering with sustainability-focused technology providers can help organizations stay ahead of regulations while enhancing their public image. Integrating IoT devices fosters a culture of responsibility and innovation while ensuring that logistics operations adapt to meet future demands.

Future Trends in IoT and Warehouse Logistics

Looking ahead, several trends in IoT and warehouse logistics management will likely shape the future of the sector. As technology continues to evolve, warehouse operations will become increasingly interconnected, allowing for far greater efficiencies. Artificial Intelligence (AI) combined with IoT will enable predictive analytics that forecasts demand, optimizing supply chains and reducing order fulfillment times. Robotics and automation are expected to further enhance operational efficiency, minimizing labor costs and creating safer environments for employees. Moreover, the importance of cybersecurity will increase as more devices connect to the internet, leading to heightened risks of data breaches. Future logistics strategies must focus on robust security protocols. Additionally, platforms integrating IoT will become more user-friendly, enabling seamless collaboration between differing systems and stakeholders. This interconnectedness will simplify data sharing and foster better decision-making across global supply chains. Ultimately, organizations prioritizing innovation and strategic investments in IoT technologies will have a competitive edge in meeting evolving customer expectations. Through adaptation and foresight, businesses can harness IoT into their future logistics management strategies effectively and sustainably.

In conclusion, the integration of IoT devices in warehouse logistics management is no longer a luxury but a necessity. Importantly, companies that embrace these technologies gain significant advantages in competitiveness, efficiency, and customer satisfaction. By enhancing visibility, automating processes, improving inventory management, and ensuring compliance, organizations set themselves apart in a crowded marketplace. However, effective implementation requires a well-defined strategy involving investment in technology solutions, stakeholder training, and commitment to continuous improvement. Embracing the benefits of IoT is essential for future-proofing logistics and adapting to the swift changes in consumer behavior. As the demand for immediate delivery and transparency continues to rise, logistics players must prioritize the adoption of connected systems. The opportunity to leverage IoT technologies has never been greater, enabling organizations to transform their operations and meet the ever-changing landscape of the logistics sector. Ultimately, those who successfully navigate the integration of IoT will position themselves not just as survivors, but as leaders in a dynamic and evolving field. As the logistics industry moves forward, businesses must focus on leveraging technology for improved performance and customer service.