Implementing AI Solutions in Supply Chain Analytics

Artificial Intelligence (AI) is revolutionizing supply chain management, transforming conventional processes into intelligent systems. Integrating AI solutions allows businesses to achieve unprecedented levels of efficiency and accuracy. AI technologies, such as machine learning and predictive analytics, enable companies to analyze vast datasets, revealing valuable insights that enhance decision-making capabilities. Embracing these technological advancements can directly impact supply chain optimization by streamlining operations and reducing costs. Companies can leverage AI to predict demand accurately, optimize inventory levels, and identify potential disruptions in the supply chain. Moreover, by utilizing AI-driven algorithms, organizations can analyze trends and patterns over time, allowing for proactive responses to market changes. This adaptability not only improves performance but also enhances customer satisfaction. Remember that implementing AI solutions is not a one-time effort but a continuous process that requires monitoring and adjustments. Organizations must consider their unique needs and the sought-after outcomes when deploying AI in supply chain analytics. Ultimately, organizations that adopt AI methodologies stand to gain a considerable competitive advantage in the ever-evolving marketplace, ensuring both longevity and relevance for their operations.

Building a successful AI strategy for supply chain analytics hinges on understanding key performance indicators (KPIs). Organizations should identify the metrics that are essential for evaluating each phase of the supply chain. Examples of crucial KPIs include order accuracy, lead time, inventory turnover, and demand forecast accuracy. Tracking these metrics will enable companies to determine the effectiveness of their AI implementations. By using AI, companies can automate data collection, leading to more accurate and timely insights. Furthermore, organizations should invest in employee training, as ensuring staff are equipped with the required knowledge will facilitate smooth AI integration. Providing employees with tools such as data visualization platforms and interactive dashboards enhances their ability to interpret and act on data-driven insights. Additionally, collaborating with AI technology providers can help organizations maintain best practices and scale their technology as needed. In doing so, companies can focus on refining their analytics capabilities to respond to real-time data, thus reinforcing their decision-making processes. Ultimately, organizations that understand their KPIs and invest in training and technology will be well-positioned to reap the benefits of AI in their supply chain analytics initiatives.

Data Quality and Governance

The success of AI solutions heavily relies on the quality and governance of data used in supply chain analytics. Poor data quality can severely impair decision-making processes, leading to financial loss and reduced operational efficiency. To mitigate these risks, organizations must implement strong data governance frameworks that ensure data accuracy, consistency, and completeness. Establishing standardized protocols for data entry across all supply chain systems is critical in maintaining high-quality data. Moreover, regular data audits and validation processes should be executed to identify and rectify inconsistencies. Organizations also need to invest in data cleaning tools and techniques to enhance the overall quality of their data. This commitment to data quality is crucial for deriving reliable insights through AI-driven analytics. Collaborating with supply chain partners can also enhance data sharing and synchronizing efforts, leading to a more holistic view of operations. Ultimately, prioritizing data quality and governance will create a robust foundation for implementing AI solutions in supply chain analytics, enabling organizations to derive actionable insights and informed decisions.

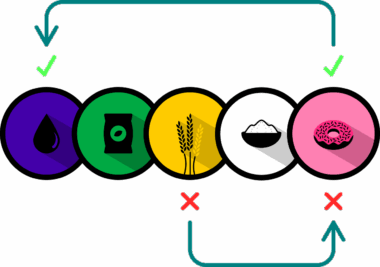

Another key aspect of implementing AI in supply chain analytics is utilizing advanced forecasting methods. Predictive analytics powered by machine learning can significantly improve demand forecasting accuracy. Traditional forecasting methods rely solely on historical data, while AI algorithms can consider numerous variables, such as weather patterns, economic indicators, and social trends. Consequently, organizations can capitalize on AI to enhance their forecasting models, allowing for better inventory management and resource allocation. By anticipating customer needs more effectively, businesses can minimize excess inventory and avoid stockouts, resulting in cost savings and increased customer satisfaction. Furthermore, advanced predictive models facilitate smoother collaboration among supply chain partners. When suppliers and distributors receive accurate forecasts, they can optimize their operations to meet anticipated demands efficiently. Organizations need to adopt an iterative approach when refining forecasting methods, as continually updating models can enhance their accuracy over time. Eventually, by investing in advanced forecasting powered by AI, companies can drive strategic decision-making and maintain a competitive edge in the market. Establishing a feedback loop to assess forecasting outcomes also helps organizations adapt more readily to changing market dynamics.

Risk Management in Supply Chain

Integrating AI solutions into supply chain analytics plays a significant role in enhancing risk management strategies. AI algorithms can analyze diverse data sources, identifying potential risks such as supplier disruptions, geopolitical factors, or economic fluctuations. By leveraging machine learning, organizations can detect anomalies and issues early, enabling proactive measures to mitigate risks. Furthermore, AI enhances scenario planning by simulating possible disruptions and their impacts on the supply chain. These simulations allow organizations to develop contingency plans and maintain operational resilience in the face of uncertainties. Additionally, utilizing geospatial analytics enables organizations to assess logistics and transportation risks in real time, optimizing routing solutions to avoid delays and inefficiencies. It is essential for organizations to embed risk management frameworks within their analytics strategies to ensure a comprehensive approach. Investing in real-time visibility tools can also aid in monitoring supplier performance and inventory levels, granting organizations greater control over their operations. Ultimately, enhancing risk management through AI-driven analytics empowers businesses to make informed decisions, ensuring supply chain resilience amidst the complexities of today’s business landscape.

Another vital consideration when implementing AI in supply chain analytics lies in fostering a culture of data literacy throughout the organization. Employees must appreciate the importance of data-driven insights in decision-making processes. Organizations can cultivate a culture of data literacy by offering workshops, training sessions, and resources that promote the effective use of data analytics tools. Encouraging employees to engage with data will empower them to make informed decisions based on AI-generated insights. Moreover, fostering cross-departmental collaboration is essential, as presenting insights from various perspectives enriches the decision-making process. Leaders should encourage open discussions around data usage and its implications for different teams. Establishing a feedback mechanism allows employees to share their insights freely, creating a sense of ownership over the company’s data initiatives. Companies that embrace data literacy tend to outperform their competitors, as their teams are better equipped to turn data into actionable strategies. Ultimately, prioritizing data literacy fosters an adaptive workforce that can thrive in an AI-driven landscape, solidifying the organization’s resilience against impending changes in the supply chain ecosystem.

Future Trends in Supply Chain Analytics

Looking ahead, several trends will shape the future of AI solutions in supply chain analytics. As technology continues to advance, AI will increasingly leverage the Internet of Things (IoT) and blockchain technologies. The integration of IoT devices will allow for real-time monitoring of assets, improving visibility and prompting timely responses to operational challenges. Furthermore, blockchain technology can facilitate transparent data sharing among supply chain partners, reinforcing trust and traceability in transactions. As organizations continue to embrace sustainability, AI will play a critical role in optimizing resource use and minimizing waste. Innovations in AI-driven analytics will support companies in identifying sustainable practices while maintaining profitability. Moreover, the adoption of autonomous systems and robotics will transform warehousing and logistics operations, streamlining workflows. Predictive analytics will continue to evolve, enabling more personalized customer experiences through targeted offerings. Staying ahead of these trends will require organizations to remain agile and adaptive to technological advancements. By embracing these innovations, companies can drive continuous improvement in their supply chain processes, ensuring competitiveness and responsiveness to market demands in the future. Supply chain analytics will undoubtedly evolve as organizations explore the endless possibilities presented by AI.

To summarize, implementing AI solutions in supply chain analytics provides various benefits that can significantly enhance operational performance. Businesses can leverage AI-driven insights to make data-informed decisions, optimize resources, and improve overall efficiency. By prioritizing data quality and governance, organizations can ensure reliable analytics outcomes that contribute to strategic growth. Furthermore, fostering a culture of data literacy promotes better engagement with AI solutions across the organization, empowering employees to act on insights confidently. As market dynamics continue to evolve, it is imperative for companies to remain at the forefront of technology through ongoing innovations and monitoring. Investing in advanced forecasting techniques, risk management strategies, and collaborative efforts with partners will bolster a company’s supply chain performance. Moreover, not adopting AI advancements presents the risk of falling behind competitors, hampering business growth. Staying informed about future trends while embracing technological advancements allows organizations to thrive in an increasingly complex supply chain landscape. In essence, integrating AI into supply chain analytics is not merely a trend but a fundamental factor in determining a company’s long-term success and resilience in an ever-changing market environment.