Automation Technologies Revolutionizing Logistics within Product Lifecycle

In the dynamic field of logistics management, automation technologies are reshaping how companies manage their product lifecycle. These technologies enable efficient integration from product conception to delivery. By automating logistics processes, organizations achieve improved accuracy, traceability, and responsiveness to market changes. Ultimately, these solutions significantly enhance overall supply chain visibility. Automation in logistics utilizes technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT). These technologies facilitate faster processing and reduce human error. AI algorithms predict demand and streamline inventory management, optimizing resources effectively. Additionally, robotics efficiently handle warehousing operations, drastically reducing order lead times. Moreover, IoT devices collect real-time data, providing insights that improve decision-making. These advancements not only facilitate timely deliveries but also enhance customer satisfaction, giving businesses a competitive edge. As these automation technologies continue to evolve, the logistics landscape is set to dramatically transform. Therefore, understanding their implementation is crucial for companies aiming to remain competitive. Embracing these innovations paves the way for cost-effective, efficient, and resilient logistics operations in a rapidly changing marketplace.

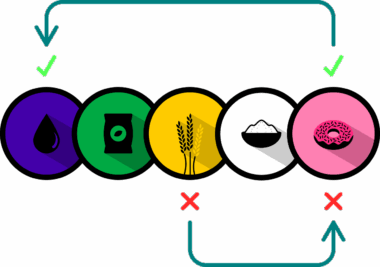

Automation technologies also significantly impact inventory management throughout the product lifecycle. Traditional inventory practices may lead to excess stock or shortages, causing delays and escalating costs. However, through automation, companies can maintain optimal inventory levels, ensuring efficient workflow. For instance, RFID technology automates tracking of products in real time, allowing teams visibility into stock status at any moment. Furthermore, predictive analytics powered by AI provides insights into inventory needs based on historical data and market trends. By proactively managing stock levels, businesses minimize waste and optimize storage capabilities. Additionally, automated ordering systems alert stakeholders when stock reaches a predetermined threshold, facilitating timely replenishment. This capability means that organizations can respond instantly to customer demands, leading to enhanced customer retention rates. Consequently, the integration of these technologies leads to improved cash flow management and reduced operational costs. Beyond logistics, such innovations amplify sustainability goals by minimizing waste. Businesses adopting these practices ensure efficient use of resources while minimizing their environmental impact, proving that automation provides both economic and ecological benefits throughout the entire product lifecycle.

Enhancing Transportation Efficiency

One critical aspect of logistics automation is enhancing transportation efficiency within the product lifecycle. Efficient transportation is essential for timely deliveries and reduced operational costs. Automated routing systems, utilizing real-time data, assist companies in selecting optimal delivery routes. This reduces fuel consumption and minimizes delays. By offering alternatives such as predictive traffic modeling, these systems allow logistics managers to make informed decisions. Furthermore, automated loading and unloading processes improve turnaround times at shipping docks, enhancing overall productivity. The utilization of autonomous vehicles further supports the advancement of transportation by eliminating human factor delays. In addition, these self-driving technologies also adhere to safety regulations, lowering the risk of accidents. The integration of these transportation automation systems ensures goods deliver on time and optimally utilize resources. Undoubtedly, the future of transportation in logistics will rely heavily on automated technologies. Companies that invest in these innovative solutions are poised to reap significant benefits, including reduced costs and improved service levels. Thus, adopting automated transportation systems is crucial as they herald a new era of efficiency throughout the product lifecycle.

Moreover, the rise of automation technologies continues to foster innovative approaches towards warehouse management. Smart warehousing plays a vital role within the entire product lifecycle, as it streamlines operations and maximizes efficiency. This is achieved through an integrated system of automated guided vehicles (AGVs) and robotics that facilitate seamless operations. Such advanced machinery minimizes the need for manual labor, allowing employees to focus on more strategic tasks. Moreover, robotic picking systems improve order accuracy by directly reducing human errors during the picking process. Additionally, automated inventory tracking enables precise monitoring of stock levels, ensuring optimal product availability. Consequently, these warehouse optimization strategies empower companies to handle fluctuations in demand effectively while maintaining low operational costs. Enhanced flexibility and adaptability are critical when responding to customer needs in today’s fast-paced targeting environment. As businesses increasingly adopt these smart technologies, they ensure efficiency throughout the entire product lifecycle and improve their competitive advantage. Thus, the evolution of warehouse automation is pivotal to sustainable growth in logistics management.

The Importance of Data Analytics

Data analytics is another significant pillar in the logistics automation landscape throughout the product lifecycle. Organizations increasingly rely on data to drive their decision-making processes, allowing them to remain competitive. By harnessing the power of data analytics, companies gain valuable insights into consumer behavior and inventory trends. This information allows logistics managers to adjust strategies efficiently, aligning their operations with market demands. Moreover, advanced analytics tools track key performance indicators (KPIs) to identify areas needing improvement. With constant evaluation, businesses can implement new practices that enhance efficiency and customer satisfaction. Additionally, predictive analytics creates forecasts based on historical data, enabling stakeholders to anticipate fluctuations in demand accurately. Embracing these data-driven techniques empowers logistics networks to minimize costs and optimize resources effectively. Furthermore, the ability to analyze and adapt fosters a culture of continuous improvement within organizations. As automation technologies continue to evolve, integrating sophisticated data analytics becomes paramount for businesses that wish to thrive in the competitive landscape of logistics. Thus, leveraging data analytics enables organizations to remain agile and adaptive throughout the entire product lifecycle.

Training and workforce development are essential factors to consider when implementing automation technologies in logistics. Businesses that invest in upskilling their workforce facilitate successful technology adoption while ensuring employees remain engaged. Training programs tailored to new technologies help workers develop critical skills necessary for operating automated tools and systems. Moreover, organizations must foster a culture of innovation and continuous learning, empowering employees to embrace changes. Maintaining communication channels ensures all team members are well-informed about updates and can contribute their insights. Furthermore, creating a support system that encourages collaboration among employees enhances adaptation to new processes. Additionally, involving employees in decision-making promotes a sense of ownership and positive morale within the workplace. As automation reshapes logistics operations, a well-trained workforce will effectively manage transitions while maximizing productivity. A focus on employee engagement and development leads to a stronger, more resilient organization. Thus, understanding the importance of workforce readiness is crucial for businesses looking to leverage automation technologies during product lifecycle management. Empowering workers guarantees smooth technology integration and lays the groundwork for sustainable growth.

Conclusion: The Future of Logistics Automation

In conclusion, automation technologies are making a profound impact on logistics within the product lifecycle. These advancements enhance efficiency, reduce costs, and improve customer experiences, redefining industry standards. Organizations embracing these innovations are likely to gain significant competitive advantages, as they can navigate shifts in consumer demands with agility. The integration of robotics, AI, IoT, and data analytics ensures businesses can streamline their operations while maintaining high service levels. Moreover, the emphasis on workforce development highlights the balanced approach needed to address both technology implementation and employee engagement. As these technologies continue to evolve, companies must remain adaptable and proactive in their strategies. Continuous monitoring of market trends and technology innovations will be vital for organizations aiming to remain at the forefront of logistics management. The future is undoubtedly promising, with automation promising to improve efficiency throughout the product lifecycle significantly. Embracing these changes ultimately leads to sustainable growth and development that benefits both companies and their customers alike.

In summary, the rise of automation technologies in logistics within product lifecycle management offers significant opportunities. Companies that proactively adopt these innovations will succeed in a rapidly changing marketplace. As automation reshapes operational efficiency and fosters collaboration, stakeholders must embrace continuous improvement. The journey towards fully automated logistics systems will require businesses to invest strategically in their workforce and technology capabilities, ensuring a seamless transition. Therefore, recognizing the transformative potential of these advancements is crucial for any organization focused on the future. Ultimately, integrating automation technology will create a more flexible and resilient logistics environment.