Optimizing Supplier Performance Through Data Analytics

In today’s highly competitive market, companies are striving to enhance their supply chain efficiency. Implementing data-driven decision-making strategies leads to better supplier performance optimization. By effectively utilizing advanced analytics, organizations can transform raw data into actionable insights. This approach minimizes risk, reduces inefficiencies, and ensures that resources are allocated optimally. To achieve these outcomes, it is essential to establish strong data governance protocols that identify what data is needed and how to maintain its quality. Moreover, companies should invest in robust analytics tools that enable real-time data processing. These tools can help monitor supplier performance metrics and generate reports that inform crucial business decisions. Additionally, engaging suppliers in the analytic process fosters transparency and collaboration, encouraging them to contribute to improvement initiatives. Employing predictive analytics can further advance supply chain performance by anticipating potential disruptions before they occur. In summary, utilizing data analytics is not merely a trend; it is an essential component of successful supply chain management.

Supplier performance analytics involves collecting, analyzing, and interpreting various performance metrics that are critical for achieving operational excellence. Organizations must focus on key performance indicators (KPIs) relevant to supplier performance. These KPIs may include on-time delivery rates, quality assurance metrics, cost performance, and responsiveness to inquiries. By gathering this data systematically, companies can assess suppliers more effectively. Furthermore, employing benchmarking against industry standards can provide valuable contexts for this assessment. Understanding a supplier’s relative performance allows organizations to identify strengths and weaknesses swiftly. It also enables them to prioritize improvement efforts where they matter most. To locate the root causes of issues, organizations might want to perform a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) on their top suppliers. Regular reviews can help maintain focus on improvements and accountability. In addition, open discussions based on analytic outcomes can build stronger relationships with suppliers, fostering an environment conducive to innovation. Finally, establishing collaborative programs that implement change based on analytics can lead to mutually beneficial outcomes.

The Role of Predictive Analytics in Supplier Performance

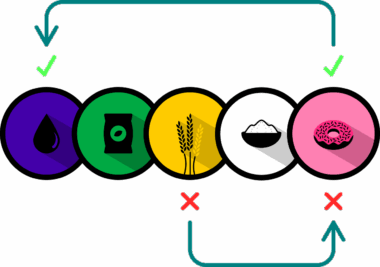

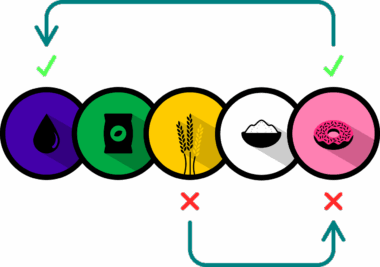

Predictive analytics plays a significant role in optimizing supplier performance by leveraging historical data to forecast future trends. Companies can analyze trends and identify patterns that could indicate potential risks or opportunities within the supplier network. This forward-looking perspective is invaluable in decision-making processes, especially when confronting uncertainties, such as fluctuating demand or supplier capabilities. Predictive models can be built using techniques such as regression analysis and machine learning algorithms. These models will help organizations visualize outcomes and know which suppliers might underperform under specific conditions. Manufacturers, for example, can anticipate delays based on previous delivery data, enabling them to mitigate disruptions quickly. Furthermore, predictive analytics can guide supplier selection by evaluating past performances and their impact on overall supply chain effectiveness. Companies can also use this data to negotiate better contract terms based on reliable forecasts. When effectively integrated, predictive analytics transforms not just the relationship with suppliers but also enhances the entire supply chain ecosystem.

Real-time data monitoring offers companies an edge in understanding supplier performance dynamics. Employing dashboards and visualization tools enables stakeholders to review metrics instantly. These visuals allow for immediate action, ensuring that any discrepancies with supplier performance are addressed proactively. Moreover, real-time monitoring provides insights into supply chain variability, which can be influenced by numerous external factors such as market trends and geopolitical situations. Companies that can access timely data are better positioned to adapt their strategies and operational workflows. It is crucial to leverage technology that integrates with existing systems to provide a seamless flow of information. Cloud-based solutions, for instance, can offer centralized repositories for data efficient sharing between all involved parties. Moreover, integrating Internet of Things (IoT) technologies can provide additional layers of data collection from physical assets, which ensure that insights are not just historical but also encompass real-time performance metrics. Ultimately, fostering a culture of agility and responsiveness in supplier management can lead to sustainable competitive advantages.

Enhancing Supplier Collaborations through Analytics

Effective supplier collaboration is integral to optimizing performance and efficiency. Data analytics serves as a foundation to build these collaborations, ensuring that both parties work towards shared objectives. Sharing performance data transparently encourages accountability, helping suppliers understand expectations and areas for improvement. Moreover, collaborative forecasting can enable suppliers to align their production schedules with client demands, reducing stockouts and excess inventory situations. Enhanced communication channels, facilitated by analytics, allow real-time feedback to encourage continuous improvement. Furthermore, joint problem-solving initiatives, based on analytical insights, can lead to innovative solutions that benefit both suppliers and buyers. Utilizing periodic review meetings to analyze key metrics can also strengthen partnerships. During these collaborations, organizations should foster an environment where suppliers feel valued and included in decision-making processes. This inclusivity promotes commitment not just to meeting targets but also to enhancing future performance. By leveraging technology and data analytics, businesses can uplift supplier collaboration, which ultimately leads to enhanced efficiency and resilience across the supply chain.

The key to successful supplier performance analytics lies in the effective deployment of technology. Companies need to adopt user-friendly platforms that allow for data capture and analysis effortlessly. This adoption fosters an environment where stakeholders can engage with data without requiring advanced expertise. Ensuring that employees are trained to utilize these tools maximizes their effectiveness. Furthermore, organizations should focus on establishing clear communication pathways relating to data reporting and performance appraisals. Misalignment in understanding analytics can lead to miscommunication and operational inefficiencies. Additionally, ongoing training programs that enhance data literacy will empower all employees, driving further engagement with analytics tools. Companies should also consider utilizing third-party analytics consultants who have expertise in supplier performance enhancement. This external perspective can offer innovative ideas and frameworks that internal teams may overlook. Ultimately, embracing analytics technology is not a singular effort but a continuous journey that requires consistent evaluation and iteration to ensure sustained supplier performance improvement.

Conclusion: Future Directions in Supply Chain Analytics

As the landscape of supply chain analytics continues to evolve, organizations must remain adaptive and proactive. The future of supplier performance optimization will likely revolve around emerging technologies such as artificial intelligence and machine learning, which will further enhance predictive capabilities. These advancements will enable companies to harness even more complex data sets, allowing for deeper insights into supplier dynamics. Furthermore, there will be a noticeable shift towards predictive rather than reactive models, aiming to identify potential issues before they escalate into problems. Cloud computing will continue to play a critical role in facilitating data accessibility and collaboration between organizations and suppliers. Additionally, the rise of blockchain technology may revolutionize transparency in supplier relations by providing immutable records of performance metrics and transactions. As sustainability becomes a focal point of supply chain operations, integrating data analytics to assess environmental impact will be crucial. In conclusion, the focus on data-driven approaches in supplier performance management will only intensify, pushing companies towards more sustainable, efficient, and collaborative supply chain practices.

The future of supply chain analytics will bring even greater improvements. Rather than merely reactive analytics, businesses must switch to proactive approaches. Suppliers will need to be engaged continuously to foster innovation and adaptability. Embracing integrated platforms will facilitate seamless information sharing while ensuring alignment in initiatives between firms. Thus, synergizing efforts will yield more significant outcomes. Collaborating on more extensive supply chain networks will enable companies to scale their analytical capabilities, paving the way for holistic optimization. Companies like Procter & Gamble have shown that leveraging comprehensive analytics can help in supplier engagement and strengthen competitive advantage. As firms incorporate emerging technologies, the discussions surrounding best practices will continue to advance. Electrifying insights generated from AI will fast-track transitions toward smarter supply chain practices. Additionally, as customers demand tailored experiences, analytics driven by customer preferences will soon dominate the space of supplier relationships. By anticipating customer behaviors based upon data, organizations can revolutionize how they interact with suppliers. To conclude, the journey towards optimizing supplier performance remains a key focus that will only compound in significance as the market continues to evolve.