Leveraging IoT Devices to Improve Vendor Managed Inventory Accuracy

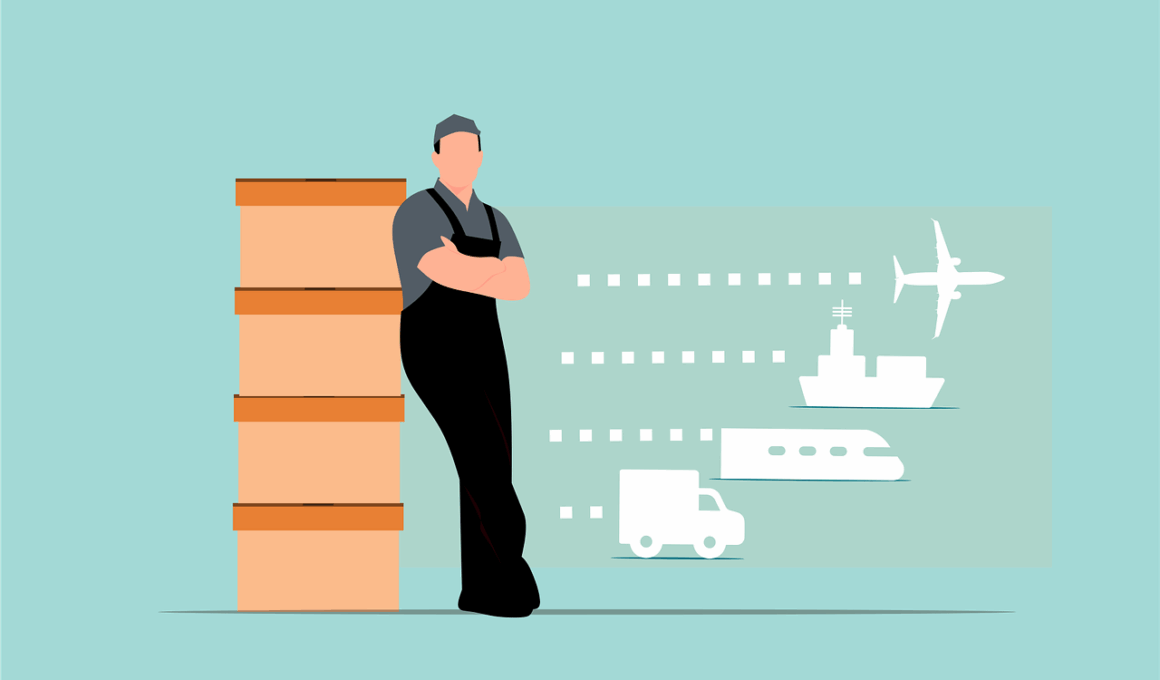

In today’s fast-paced business environment, accuracy in inventory management is crucial for success. Vendor Managed Inventory (VMI) has emerged as a popular method that enables vendors to manage a retailer’s inventory levels. By utilizing the Internet of Things (IoT) devices, businesses can enhance their VMI processes drastically. The integration of IoT technology allows real-time tracking and monitoring, which provides precise data about inventory levels. This cuts down the chances of stockouts or excess stock that can lead to financial losses. Furthermore, IoT devices such as smart shelves, RFID tags, and sensors can offer insights into product movements and patterns. Improved accuracy in inventory can result in better cash flow management. In recent trends, many companies are adopting IoT devices to streamline their supply chain processes. The synchronization of vendor and retailer data ensures that decisions are made based on actual consumption patterns. The partnership between IoT technology and VMI fosters a collaborative approach between the vendors and retailers ensuring mutual benefits. Hence, the journey to optimizing vendor managed inventory starts with embracing IoT solutions. Businesses can choose the right technology that fits their operational needs effectively.

The adoption of IoT in Vendor Managed Inventory paves the way for several benefits that boost supply chain efficiency. By implementing IoT solutions, organizations can improve accuracy, reduce operational costs, and enhance customer satisfaction. For instance, with sensors integrated into storage facilities, inventory levels can be monitored in real-time. This enables timely replenishment before stocks run low, minimizing disruption in operations. Moreover, the data collected from IoT devices facilitates better forecasting and planning. Retailers can analyze historical data, seasonal trends, and customer preferences to adjust inventory levels accordingly. This leads to optimal stock levels, which significantly reduces carrying costs. Vendors are also empowered by this data, allowing them to make informed decisions regarding purchasing and production capacities. In addition, IoT devices streamline communication between vendors and retailers, allowing for quick updates on product availability and need for restocking. The rapid sharing of information enhances collaboration and trust within the supply chain. To ensure successful implementation of IoT in VMI, organizations must invest in infrastructure and staff training. Embracing technology not only streamlines operations but also positions businesses competitively in the marketplace.

IoT devices are transforming the landscape of Vendor Managed Inventory through automation and real-time visibility. One of the critical aspects of VMI is data accuracy, which is pivotal for effective replenishment strategies. With IoT, businesses can automate data entry processes that were previously manual; this significantly reduces human error possibilities. For example, using barcodes or RFID systems helps track shipments and inventory movement seamlessly. This level of automation fosters an environment where data-driven decisions become easier, ultimately enhancing the overall productivity of supply chain operations. In addition, integrating cloud-based solutions with IoT devices offers scalability, allowing businesses to adapt easily to changing market demands. The ability to analyze vast amounts of data provides actionable insights, promoting continuous improvement. Retailers are also better equipped to respond to consumer behaviors using real-time data. Furthermore, the collection and sharing of data enable effective collaboration, ensuring all stakeholders remain aligned on goals. Enhanced communication will reduce discrepancies and improve forecasting accuracy. Ultimately, leveraging automation through IoT results in a more resilient supply chain, better equipped to face challenges and uncertainties in today’s market.

Challenges in Implementation of IoT in VMI

Despite the advantages that IoT devices bring to Vendor Managed Inventory, there are several challenges that businesses face when implementing this technology. First, the initial setup cost for IoT infrastructure can be significant. Many organizations hesitate due to concerns about ROI. Integration with existing systems can also prove to be complex, especially in cases where legacy systems are prevalent. Organizations must evaluate the current technology landscape before introducing IoT to ensure compatibility and ease of integration. Furthermore, employee resistance to adopting new technologies and changing established processes can hinder progress. Training and educating employees about the benefits of IoT is crucial for successful implementation. Another concern is the security and privacy of data collected by IoT devices. Companies must invest in robust cybersecurity measures to protect sensitive information from potential breaches. The increase in connected devices also amplifies vulnerabilities which can lead to larger scale disruptions. Therefore, addressing these challenges proactively by securing budget approvals and conducting pilot tests for seamless integration can increase the chances of successful adoption. By tackling these barriers, businesses can reap the long-term benefits of enhanced inventory management.

Furthermore, effective collaboration between the vendors and retailers is essential for the successful implementation of VMI using IoT devices. The very essence of Vendor Managed Inventory is founded on strong partnerships that emphasize transparency and trust. Both parties must be willing to share relevant data, insights, and forecasts to achieve optimal inventory management. Establishing clear communication channels allows for instant feedback and facilitates the speedy resolution of issues that may arise. Regular meetings and reviews help reinforce the collaborative efforts while allowing both parties to strategize on demand fluctuations effectively. Additionally, setting performance metrics and sharing accountability ensures that both vendors and retailers stay aligned. The introduction of agreed-upon KPIs can further guide the relationship, helping assess the effectiveness of the VMI strategy over time. Taking a collaborative approach reduces conflicts and promotes joint ownership of inventory performance. In emphasizing a partnership model, businesses can create a supply chain environment that thrives on mutual benefit. Ultimately, successful VMI relies as much on relationships as on technology, with IoT serving as the tool that enables better cooperation and information sharing.

The Future of VMI with IoT Integration

Looking ahead, the future of Vendor Managed Inventory with IoT integration appears promising. As technology continues to advance, new tools and solutions are expected to emerge, offering even greater capabilities for inventory management. Innovations such as advanced analytics, machine learning, and artificial intelligence will facilitate better decision-making processes. These technologies will enhance predictive analytics, enabling businesses to anticipate not only demands but also supply chain disruptions. This proactive approach can revolutionize how companies approach inventory management strategies, mitigating risks before they escalate into costly issues. Moreover, IoT devices will become increasingly affordable, making them accessible for businesses of all sizes. With more organizations adopting IoT solutions, the industry is likely to witness better standardization, which can simplify partnerships between vendors and retailers. Real-time data will foster a data-driven culture, promoting agility and responsiveness across the supply chain. Effective collaboration coupled with advanced technology will ensure businesses can thrive amid dynamic market conditions. As organizations embrace the evolving landscape of supply chain management, the trajectory towards accuracy and efficiency in VMI will become more pronounced, creating a competitive edge in the marketplace.

In conclusion, leveraging IoT devices to improve Vendor Managed Inventory accuracy is not just a trend; it is a vital shift towards enhancing supply chain efficacy. By investing in the right technologies and fostering strong relationships with partners, organizations can significantly improve inventory management processes. The comprehensive benefits of adopting IoT, such as enhanced accuracy, reduced costs, and improved collaboration, cannot be overstated. Overcoming implementation challenges will pave the way for successful deployment of VMI strategies. Ongoing education and transparent communication among stakeholders further amplify the effectiveness of IoT solutions. A forward-thinking approach will allow businesses to stay competitive in today’s rapidly changing market landscape. As technology continues to advance, companies that remain agile and successfully integrate innovative solutions can position themselves as industry leaders. The future of VMI lies in embracing technology while nurturing strong vendor-retailer partnerships. The symbiotic relationship created by IoT devices will lead to better inventory outcomes, ultimately satisfying customer demands. In a world where accuracy is paramount, utilizing IoT to refine VMI practices will surely yield substantial rewards in operational success.

Ultimately, leveraging IoT devices to improve Vendor Managed Inventory accuracy represents a transformative step towards optimizing supply chain management. By combining technological advancements with collaborative practices, organizations can create a more effective inventory management framework that benefits all participants.