Digital Transformation and Supply Chain Integration

Digital transformation is transforming businesses across various sectors, especially in supply chain integration. Organizations are increasingly leveraging technology to synchronize operations, streamline processes, and enhance product flow. Embracing cloud computing, artificial intelligence, and data analytics not only boosts efficiency but also fosters agility within supply chains. These technologies enable real-time visibility, allowing companies to anticipate demand trends, optimize inventory management, and respond effectively to fluctuating markets. Furthermore, with automation tools, tedious manual tasks are reduced, enabling staff to focus on strategic planning and decision-making. By integrating various supply chain components, companies can ensure a seamless flow of information and materials, ultimately improving customer satisfaction. Investing in digital tools facilitates collaboration across departments, resulting in a unified approach to supply chain challenges. The shift towards a digital-first mindset is no longer optional; it is imperative for businesses that wish to remain competitive in their respective industries. By aligning digital strategies with supply chain objectives, organizations can achieve a sustainable competitive advantage through improved productivity and efficiency.

The benefits of supply chain integration through digital transformation extend beyond mere operational improvements. Enhanced collaboration among suppliers, manufacturers, and customers fosters transparency in relationships, which is crucial for long-term success. By sharing real-time data, relevant parties can make informed decisions, resulting in better inventory management and reduced lead times. Successful digital integration also enhances the ability to respond quickly to market changes and consumer demands. Companies can use data-driven insights to identify areas for improvement, streamline processes, and eliminate inefficiencies. As a result, organizations increase their responsiveness and adapt to new market dynamics faster. Moreover, improved supply chain integration can lead to significant cost savings by optimizing resource utilization and reducing waste. Digital transformation allows for better forecasting, leading to more accurate predictions and reduced excess inventory. Additionally, it helps companies align their supply chain strategies with overall organizational goals, ensuring everyone works towards the same objectives. This holistic view of supply chain management is essential to thrive in an increasingly complex business landscape. Organizations that embrace these changes position themselves for success, taking advantage of the numerous opportunities that technology affords.

Challenges in Digital Transformation

While the advantages of digital transformation in supply chain integration are clear, several challenges will also need to be addressed. Implementing new technologies often requires a significant investment in both software and hardware, which may not be feasible for all organizations. Furthermore, there is a steep learning curve as employees must adapt to new systems and workflows. Resistance to change can pose another significant obstacle, as employees may be reluctant to relinquish traditional practices in favor of unfamiliar digital processes. Companies often struggle to demonstrate the value of these new initiatives, making it difficult to gain buy-in from stakeholders. Data security is another pressing concern as organizations increase their digital footprints, potentially exposing sensitive information to cyber attacks. Additionally, businesses must ensure that their suppliers also embrace digital transformation to create a fully integrated supply chain ecosystem. The lack of standardized protocols and interoperability among different systems can result in further complications. Organizations must invest in training, secure data management practices, and collaborative strategies to mitigate these challenges effectively. Overcoming these obstacles is essential to achieve the full benefits of digital supply chain integration.

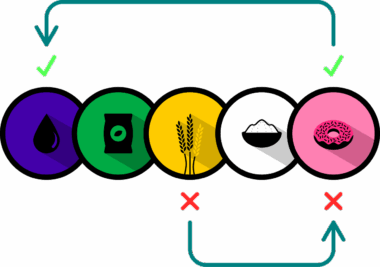

One of the key strategies for successful digital transformation in supply chain integration is adopting an incremental approach. Rather than attempting to overhaul entire systems at once, organizations can choose to implement changes step-by-step. This allows for adjustments based on real-time feedback and minimizes disruptions to ongoing operations. Additionally, companies should prioritize integration with existing systems, ensuring that new tools work harmoniously with legacy systems. This approach can help ease the transition and promote a smoother adoption process. Moreover, establishing clear goals and metrics for measuring success can guide organizations in their digital journey. These targets should focus on specific performance indicators relevant to supply chain management, such as cycle time reduction, inventory accuracy, and customer satisfaction. It is also crucial to engage employees throughout the process, encouraging participation and input from various departments. By fostering a culture centered around collaboration and continuous improvement, organizations can build resilience within their supply chains. Furthermore, leveraging partnerships with technology providers can yield valuable insights and support, ensuring that companies stay competitive and informed about emerging innovations in supply chain management.

Future Trends in Supply Chain Integration

As businesses continue to adapt to the evolving landscape of supply chain management, several future trends are anticipated to shape digital transformation. The increased emphasis on sustainability will drive organizations to adopt more eco-friendly practices throughout their supply chains. Companies will utilize digital technologies to monitor their carbon footprint, optimize logistics to reduce emissions, and promote recycling and waste reduction initiatives. Additionally, the rise of blockchain technology is expected to revolutionize supply chain integration, providing transparency and traceability that will enhance trust among stakeholders. Smart contracts can automate processes, ensuring compliance with contract terms and eliminating potential disputes. Moreover, the Internet of Things will play a vital role in gathering real-time data from various touchpoints, allowing organizations to monitor assets and inventory levels. Predictive analytics will leverage this data to forecast demand more accurately, enabling proactive decisions. Artificial Intelligence will also revolutionize supply chain operations through advanced algorithms that enhance decision-making and increase automation and responsiveness, readying organizations for the challenges ahead. These trends will redefine supply chain management, emphasizing innovation, sustainability, and adaptability in a rapidly changing business environment.

Ultimately, digital transformation and supply chain integration are more than just buzzwords; they represent a paradigm shift in how organizations operate. By embracing technology, businesses can unlock new opportunities for growth and efficiency, transforming the way they collaborate, communicate, and deliver value to customers. The investment in digital tools and systems should be viewed as a long-term strategy rather than a short-term fix, as the returns on investment can be substantial. Organizations that successfully integrate their supply chains will position themselves at the forefront of their industries, ready to capitalize on emerging trends and navigate potential disruptions. The future of supply chain management lies in adopting a proactive, data-driven mindset that emphasizes responsiveness, agility, and collaboration. Stakeholders must prioritize continuous learning and adaptation, sharing knowledge and insights along the supply chain. By doing so, organizations can strengthen their competitive advantage and foster sustainable practices that benefit not only their bottom lines but also the communities they serve. A future-oriented approach to digital transformation will ensure the longevity and resilience of supply chains in an increasingly uncertain world.

In summary, the intersection of digital transformation and supply chain integration plays a vital role in shaping modern business practices. Companies must recognize the importance of integrating advanced technologies into their operations to achieve efficiency and resilience in the face of challenges. This transformation involves a commitment to continuous improvement, employee engagement, and strategic investment in technology. By fostering a culture of collaboration and innovation, organizations can leverage their digital capabilities to address evolving consumer needs and market trends. Supply chain integration is no longer merely a function of logistics; it encompasses a broader strategic vision that underscores the importance of cohesive operations. Building strong partnerships with suppliers, utilizing data analytics for informed decision-making, and capitalizing on technological advancements are among the pillars of successful integration. Companies must also remain vigilant about security and compliance as they embrace these new technologies. Through strategic planning, incremental implementation, and a commitment to adapting to change, organizations can lay the groundwork for a more integrated and digitally transformed supply chain. Such efforts will not only enhance productivity and efficiency but will also drive innovation and sustainable growth.